English

Views: 222 Author: Tomorrow Publish Time: 2025-07-13 Origin: Site

Content Menu

● Understanding Aluminum Profiles and Their Importance

● Key Factors to Consider When Choosing Aluminum Profile Manufacturers

>> 1. Product Quality and Standards

>> 2. Range of Products and Customization Options

>> 3. Technological Capabilities and Innovation

>> 5. Delivery Times and Reliability

>> 6. Reputation and Customer Service

>> 7. Sustainability Practices

● Additional Considerations for Industrial Aluminum Profiles

● Steps to Choose the Best Aluminum Profile Manufacturer

● FAQ

>> 1. What certifications should I look for in aluminum profile manufacturers?

>> 2. How important is customization when choosing an aluminum profile manufacturer?

>> 3. Can I rely on customer reviews to select a manufacturer?

>> 4. What role does technology play in aluminum profile manufacturing?

>> 5. How do I ensure timely delivery from my aluminum profile supplier?

Choosing the right aluminum profile manufacturer is a critical decision that can significantly influence the success of your project. Aluminum profiles are widely used across industries such as construction, automotive, aerospace, and manufacturing due to their lightweight, durability, and versatility. However, not all manufacturers deliver the same quality, customization options, or service. This comprehensive guide will help you understand the essential factors to consider when selecting the best aluminum profile manufacturer for your specific needs.

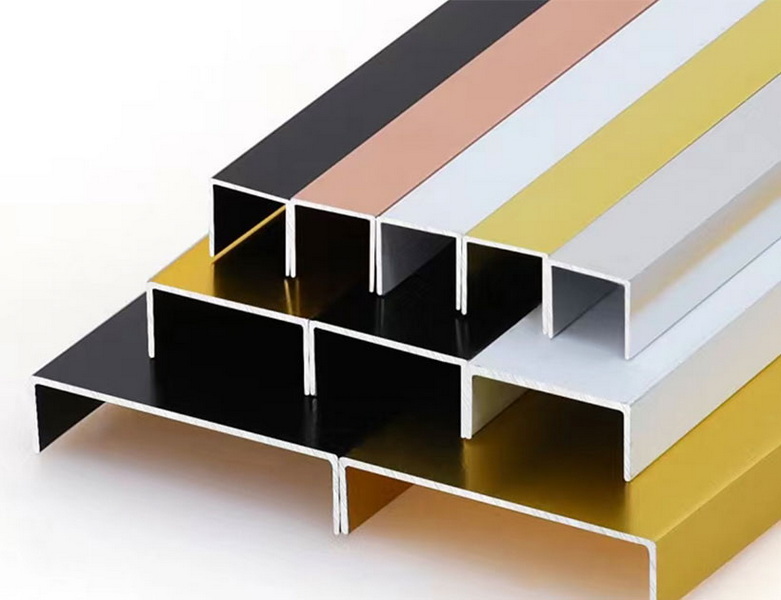

Aluminum profiles come in various shapes, sizes, and alloys, each designed for particular applications. For example, T-slot aluminum profiles are popular for building frameworks and enclosures, while L-shaped profiles are often used in structural applications. Some manufacturers also offer decorative options like wood grain aluminum profiles, which combine aesthetic appeal with metal durability.

Knowing the type of aluminum profile your project requires is the first step toward choosing the right manufacturer. This knowledge will help you evaluate manufacturers based on their product range and specialization.

Quality is paramount when selecting an aluminum profile manufacturer. High-quality profiles ensure durability, corrosion resistance, and structural integrity. To assess quality, consider the following:

- Raw materials: The manufacturer should use premium-grade aluminum alloys suited for your application.

- Manufacturing processes: Advanced extrusion and finishing techniques contribute to superior products.

- Certifications: Look for ISO 9001 or other relevant international quality certifications.

- Quality control: Reliable manufacturers have stringent quality checks and offer samples for testing.

Visiting the manufacturing facility can also provide insight into their commitment to quality and production standards.

Every project has unique requirements, so flexibility in product offerings is essential. The best aluminum profile manufacturers provide:

- A wide variety of profile shapes and sizes.

- Customization in dimensions, finishes, and colors.

- Specialized profiles for different industries, such as architectural, industrial, or decorative aluminum profiles.

Manufacturers that can tailor profiles to your exact specifications will save time and reduce costs by minimizing the need for additional processing.

Manufacturers equipped with modern machinery and innovative extrusion technology typically produce higher quality and more precise aluminum profiles. This capability also allows them to handle complex designs and maintain tight tolerances.

Technology also impacts production efficiency, which can influence delivery times and pricing. Manufacturers who invest in die design and development can provide custom profiles that perfectly match your project needs, offering innovative and cost-effective solutions.

While cost should not be the sole deciding factor, it is important to find a manufacturer that offers competitive pricing without compromising quality. Consider:

- Transparent pricing structures.

- Volume discounts for large orders.

- The balance between price and product longevity.

Avoid manufacturers offering unrealistically low prices, as this may indicate subpar materials or processes. For instance, some manufacturers use recycled aluminum ingots that may contain impurities, resulting in inferior product quality. Choosing a supplier that uses high-quality raw materials ensures better durability and performance.

Timely delivery is crucial to keep your project on schedule. Evaluate the manufacturer's:

- Production capacity and lead times.

- Ability to handle urgent or large orders.

- Track record for meeting deadlines.

Reliable manufacturers communicate clearly about delivery schedules and manage logistics efficiently. Ensuring they have adequate inventory and a robust supply chain can prevent costly project delays.

A manufacturer's reputation reflects their reliability and professionalism. Research:

- Customer reviews and testimonials.

- Industry references.

- Longevity and experience in the aluminum profile market.

Good customer service is equally important. Choose manufacturers who are responsive, willing to collaborate, and provide technical support throughout your project. Technical assistance can be invaluable, especially for complex profiles or when troubleshooting arises during production or application.

Increasingly, sustainability is a factor in supplier selection. Manufacturers who use eco-friendly materials and processes not only reduce environmental impact but also enhance your project's green credentials. This includes using recycled materials responsibly, reducing energy consumption, and minimizing waste during production.

Industrial aluminum profiles require specific attention to mechanical properties such as strength, hardness, corrosion resistance, weldability, and machinability. Depending on your application, you may need profiles made from particular aluminum alloys:

- Strength: Profiles made from alloys like 6061 or 7075 offer high tensile strength suitable for structural applications.

- Corrosion resistance: Anodized or powder-coated finishes can enhance durability in harsh environments.

- Machinability: Some profiles are easier to cut, drill, or weld, which can reduce fabrication time and costs.

Surface treatments such as anodizing, powder coating, or fluorocarbon finishes not only improve aesthetics but also increase resistance to wear and corrosion, extending the life of your aluminum profiles.

1. Define your project requirements: Understand the types of aluminum profiles needed, including size, shape, alloy, and finish.

2. Research potential manufacturers: Look for companies with a strong industry presence and positive feedback.

3. Request samples and quotations: Evaluate product quality and pricing.

4. Assess manufacturing capabilities: Consider technological strength and customization options.

5. Check certifications and quality control: Verify compliance with industry standards.

6. Evaluate customer service and communication: Ensure they are responsive and supportive.

7. Make a trial order: Test their delivery and product consistency before committing to large-scale orders.

8. Establish a partnership: Maintain ongoing communication and performance reviews.

Selecting the best aluminum profile manufacturer is a multifaceted process that requires careful consideration of quality, product range, technological capabilities, pricing, delivery reliability, and reputation. By thoroughly evaluating these factors and aligning them with your project's specific needs, you can secure a manufacturing partner who will contribute to the success and efficiency of your project. A strong partnership with a reputable aluminum profile manufacturer not only ensures high-quality materials but also fosters innovation and reliability throughout your project lifecycle.

Look for international quality certifications such as ISO 9001, ASTM standards, and any industry-specific approvals that demonstrate adherence to quality and safety standards.

Customization is crucial as it allows you to get profiles tailored to your exact specifications, reducing the need for additional modifications and ensuring better integration into your project.

Yes, customer reviews and testimonials provide valuable insights into a manufacturer's reliability, product quality, and customer service. However, they should be considered alongside other evaluation criteria.

Advanced technology leads to higher precision, better surface finishes, faster production times, and the ability to produce complex profiles, all of which benefit your project.

Choose manufacturers with proven production capacity, clear communication about lead times, and a track record of meeting deadlines. Starting with a smaller order can help verify their reliability.

Stainless Steel Sheets Vs Galvanized Steel Sheets: Pros And Cons Compared

Stainless Steel Sheets Vs Aluminum Sheets: Which One Suits Your Project?

Cold Rolled Vs Hot Rolled Stainless Steel Sheets: Key Differences Explained

How To Choose Stainless Steel for Industrial Guardrails And Railings?

How Do Aluminum Windows Makers Ensure Quality And Durability?

Can an Aluminum Windows Company Handle Large-Scale Projects?