English

Views: 222 Author: Tomorrow Publish Time: 2025-07-13 Origin: Site

Content Menu

● Understanding Flexible Aluminum Profiles

>> Types of Flexible Aluminum Profiles

● Applications of Flexible Aluminum Profiles

>> 2. Architectural and Interior Design

>> 3. Automotive and Transportation

● Advantages of Flexible Aluminum Profiles

● FAQ

>> 1. What materials are used to make flexible aluminum profiles?

>> 2. How do flexible aluminum profiles differ from standard aluminum profiles?

>> 3. Can flexible aluminum profiles be used outdoors?

>> 4. Are flexible aluminum profiles compatible with LED lighting?

>> 5. What surface finishes are available for flexible aluminum profiles?

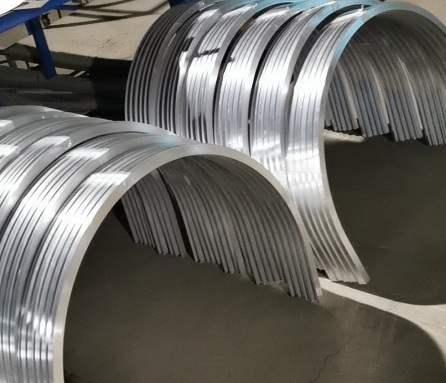

A flexible aluminum profile is a specialized aluminum extrusion designed to be bendable or adaptable to various shapes and surfaces without compromising its structural integrity. Unlike traditional rigid aluminum profiles, these flexible profiles offer versatility and customization options, making them ideal for applications where curves, bends, or irregular surfaces are involved. This article explores the nature of flexible aluminum profiles, their manufacturing, properties, and diverse applications across industries.

A flexible aluminum profile is essentially an aluminum extrusion made from high-grade aluminum alloys, often from the 6000 series, known for their excellent strength-to-weight ratio and corrosion resistance. These profiles are engineered to be bendable, either through specific design features such as segmented or slotted structures or by using thinner sections that allow controlled flexibility. The aluminum material provides durability, heat dissipation, and resistance to environmental factors.

- Flexibility: The defining characteristic, allowing bending around curves or irregular surfaces.

- Lightweight: Aluminum's low density reduces overall weight, crucial for many applications.

- Corrosion Resistance: Surface treatments such as anodizing, powder coating, or electrophoresis enhance durability.

- Heat Dissipation: Aluminum's excellent thermal conductivity helps in applications like LED lighting.

- Customizability: Available in various shapes, sizes, and finishes to suit specific needs.

Flexible aluminum profiles come in various types depending on their design and intended use:

- Segmented Profiles: These have small cuts or slots along their length, allowing them to bend easily while maintaining structural integrity.

- Thin-Walled Profiles: Made with thinner aluminum walls that allow bending without cracking.

- Multi-Layered Profiles: Combining aluminum with flexible materials or rubber inserts to enhance bendability.

- Modular Profiles: Designed to be assembled in sections that can be adjusted or bent as needed.

Each type offers different degrees of flexibility and strength, enabling designers and engineers to select the best option for their specific project.

Flexible aluminum profiles are produced through extrusion, where heated aluminum billets are forced through a shaped die to create long profiles with consistent cross-sections. For flexibility, the design may incorporate:

- Segmented or Slotted Designs: Allowing the profile to bend without breaking.

- Thinner Wall Sections: Facilitating easier bending.

- Special Alloy Compositions: Enhancing ductility.

After extrusion, profiles undergo surface treatments such as anodizing, powder coating, or polishing to improve appearance and resistance to wear and corrosion.

In some cases, additional processes such as CNC machining or laser cutting are used to create precise slots or perforations that enhance flexibility. Quality control is critical to ensure that bending does not compromise the profile's structural integrity or surface finish.

One of the most prominent uses of flexible aluminum profiles is in LED lighting solutions. These profiles serve as housings for LED strips, providing:

- Protection: Shielding LEDs from dust, moisture, and physical damage.

- Heat Dissipation: Aluminum efficiently disperses heat generated by LEDs, prolonging their lifespan.

- Aesthetic Enhancement: Profiles often include diffusers (frosted or clear) to soften light and reduce glare.

- Flexibility: Profiles can be bent to fit curved surfaces, enabling creative lighting designs such as cove lighting, staircase illumination, or accent lighting.

This versatility allows designers to integrate lighting seamlessly into architectural features, furniture, or decorative elements. Flexible aluminum profiles enable lighting in places where traditional rigid profiles would be impossible to install, such as around circular columns or along curved ceilings.

Flexible aluminum profiles are used to create curved frames, trims, and decorative elements in buildings and interiors. Their ability to conform to non-linear shapes makes them ideal for:

- Curved window frames

- Rounded door trims

- Custom furniture edges

- Wall paneling with unique contours

Surface finishes can mimic wood grain or other textures, enhancing design aesthetics. Architects and interior designers often use flexible aluminum profiles to add dynamic, flowing lines to spaces, creating a modern and elegant atmosphere.

In automotive manufacturing, flexible aluminum profiles are used for lightweight structural components that require bending or shaping, such as:

- Trim moldings

- Protective guards

- Interior framing

Their lightweight nature contributes to fuel efficiency, while flexibility allows for complex design shapes. Additionally, flexible aluminum profiles are used in public transportation vehicles and aerospace applications where weight reduction and adaptability to curved surfaces are critical.

Flexible aluminum profiles enable innovative furniture designs with curved or ergonomic shapes. They are used in:

- Office furniture frames

- Shelving supports

- Display fixtures

Their durability and finish options also make them suitable for both functional and decorative purposes. The profiles can be bent on-site to fit custom designs, reducing manufacturing time and costs.

In machinery and equipment, flexible aluminum profiles are used for:

- Custom framing systems

- Sliding tracks

- Protective covers

Their adaptability allows for easy modifications and adjustments in industrial setups. Flexible profiles facilitate the creation of modular systems that can be expanded or reshaped as needed, improving efficiency and reducing downtime.

Flexible aluminum profiles are increasingly popular in the signage industry. They allow for the creation of illuminated signs with curved or unusual shapes, enhancing brand visibility and aesthetic appeal. The profiles provide a sturdy yet adaptable frame for LED strips or other lighting elements, ensuring durability and consistent illumination.

- Versatility: Can adapt to various shapes and surfaces.

- Durability: Resistant to corrosion and wear.

- Lightweight: Easier handling and installation.

- Thermal Management: Ideal for heat-sensitive applications like LEDs.

- Aesthetic Flexibility: Multiple finishes and colors available.

- Cost-Effective: Reduces need for custom fabrication or complex assembly.

- Eco-Friendly: Aluminum is recyclable, supporting sustainable manufacturing practices.

Flexible aluminum profiles are designed for ease of installation. They often come with mounting brackets, clips, or adhesive backing. Their bendability allows installers to shape profiles on-site, reducing the need for precise pre-fabrication and enabling adjustments to fit unique architectural features.

During installation, care must be taken to avoid over-bending, which can cause deformation or cracking. Specialized bending tools or jigs are often used to achieve consistent curves without damaging the profile. Additionally, flexible profiles can be cut to length using standard metalworking tools, allowing for customization on the job site.

Flexible aluminum profiles require minimal maintenance. Their corrosion-resistant surfaces help prevent rust and degradation, even in outdoor or humid environments. Cleaning with mild detergents and soft cloths is usually sufficient to maintain their appearance.

When used in lighting applications, periodic checks ensure that LED strips and diffusers remain intact and functional. Proper installation and surface treatment extend the lifespan of flexible aluminum profiles, making them a durable choice for long-term projects.

A flexible aluminum profile is a highly adaptable, durable, and lightweight solution that meets the demands of modern design and industrial applications. Its ability to bend and conform to various shapes without losing structural integrity makes it invaluable in lighting, architecture, automotive, furniture, and industrial sectors. With excellent heat dissipation, corrosion resistance, and aesthetic versatility, flexible aluminum profiles continue to expand the possibilities for innovative and functional designs. Their ease of installation, cost-effectiveness, and eco-friendly nature further enhance their appeal, making them a preferred choice for designers, engineers, and manufacturers worldwide.

Flexible aluminum profiles are primarily made from high-grade aluminum alloys, especially from the 6000 series, chosen for their strength, corrosion resistance, and ductility. Surface treatments like anodizing or powder coating are applied to enhance durability and aesthetics.

Unlike standard rigid aluminum profiles, flexible aluminum profiles are engineered to bend and conform to curved or irregular surfaces without breaking. This is achieved through design features such as segmented structures or thinner walls.

Yes, flexible aluminum profiles are suitable for outdoor use, especially when treated with corrosion-resistant coatings like anodizing or powder coating. Their durability and resistance to environmental factors make them ideal for exterior architectural elements and outdoor lighting.

Absolutely. Flexible aluminum profiles are widely used in LED lighting to house LED strips, providing protection, heat dissipation, and aesthetic enhancement with diffusers. Their flexibility allows for creative lighting designs on curved surfaces.

Flexible aluminum profiles can be finished with various treatments including anodizing, powder coating, electrophoresis, polishing, sandblasting, and even wood grain printing. These finishes improve corrosion resistance and offer a range of colors and textures.

Stainless Steel Sheets Vs Galvanized Steel Sheets: Pros And Cons Compared

Stainless Steel Sheets Vs Aluminum Sheets: Which One Suits Your Project?

Cold Rolled Vs Hot Rolled Stainless Steel Sheets: Key Differences Explained

How To Choose Stainless Steel for Industrial Guardrails And Railings?

How Do Aluminum Windows Makers Ensure Quality And Durability?

Can an Aluminum Windows Company Handle Large-Scale Projects?