English

Views: 222 Author: Tomorrow Publish Time: 2025-06-17 Origin: Site

Content Menu

● Overview of Aluminum Profile Manufacturing in Canada

● Leading Conventional Standard Aluminum Profiles Manufacturers in Canada

● Industry Applications of Conventional Standard Aluminum Profiles

● Advantages of Choosing Canadian Manufacturers for Aluminum Profiles

● Future Trends in the Canadian Aluminum Profile Industry

● FAQ

>> 1. What are conventional standard aluminum profiles?

>> 2. Which industries commonly use aluminum profiles in Canada?

>> 3. What makes Canadian aluminum profile manufacturers stand out?

>> 4. Can Canadian manufacturers provide customized aluminum profiles?

>> 5. How does the aluminum extrusion market in Canada contribute to the economy?

Aluminum profiles are essential components widely used across various industries such as construction, automotive, aerospace, and manufacturing. The demand for high-quality aluminum profiles has been steadily increasing, driven by their lightweight, durability, and versatility. Canada, with its robust industrial base, hosts several top conventional standard aluminum profiles manufacturers who have gained recognition for their precision, innovation, and commitment to quality. This article explores the leading manufacturers of conventional standard aluminum profiles in Canada, highlighting their capabilities, industries served, and contributions to the market.

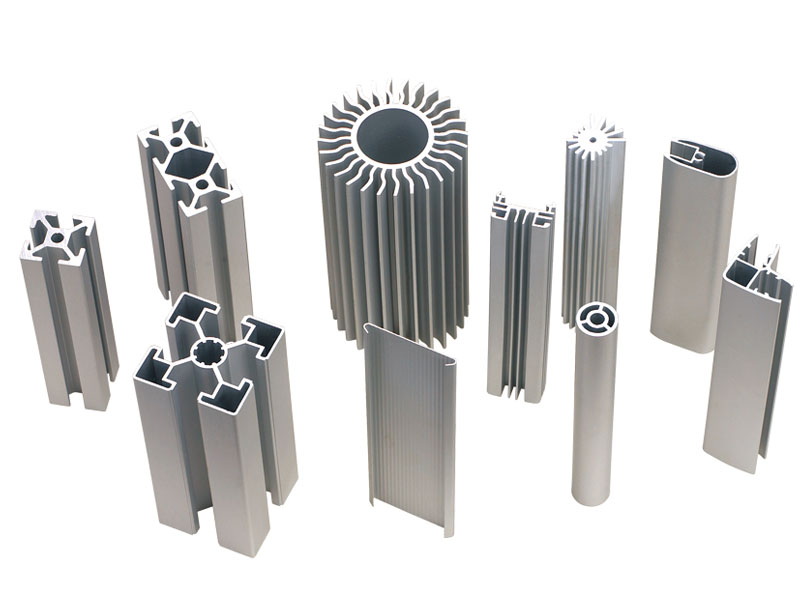

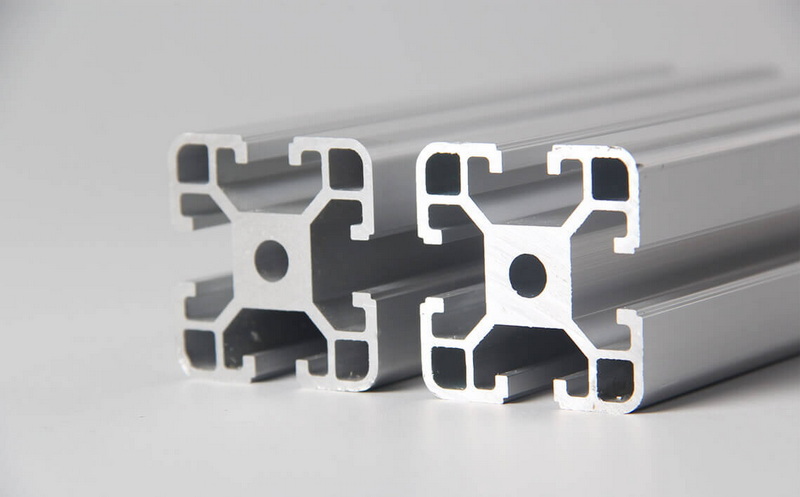

Aluminum profiles are created through extrusion processes where aluminum billets are forced through dies to form specific shapes and sizes. Conventional standard aluminum profiles refer to those produced using established extrusion techniques and standardized dimensions to meet common industrial requirements. These profiles are used in structural frameworks, window and door frames, transportation components, and more.

Canada's aluminum profile industry benefits from access to high-quality raw materials, advanced manufacturing technology, and a skilled workforce. The country's manufacturers serve both domestic and international markets, supplying aluminum profiles for diverse applications.

The Canadian aluminum extrusion industry is characterized by its ability to combine traditional manufacturing techniques with modern innovations. This blend ensures that the profiles produced meet stringent quality standards while being adaptable to the evolving needs of various sectors. The focus on sustainability and energy efficiency in production also aligns with global trends, making Canadian manufacturers competitive on the world stage.

Located in Brampton, Ontario, Almag Aluminum Inc. is one of Canada's premier producers of conventional standard aluminum profiles. With decades of experience, Almag has developed a reputation for precision-engineered aluminum solutions tailored to meet client specifications. Their manufacturing facilities are equipped with advanced extrusion and fabrication technologies, enabling them to produce high-quality profiles with consistent performance.

Almag's product range includes standard extrusions used in construction, transportation, and industrial applications. Their commitment to customization and timely delivery has made them a preferred supplier for many Canadian and international clients. Additionally, Almag emphasizes sustainable manufacturing practices, incorporating recycled aluminum and energy-efficient processes to reduce environmental impact.

Exco Technologies Limited, headquartered in Markham, Ontario, is another key player in the Canadian aluminum profile manufacturing sector. The company specializes not only in aluminum extrusion but also in die design and manufacturing, offering comprehensive solutions from concept to finished product. Exco's innovative approach allows them to meet evolving industry demands, especially in automotive and aerospace sectors.

Exco Technologies has a global footprint, serving markets beyond Canada, and is known for its high-quality conventional standard aluminum profiles that comply with rigorous industry standards. Their investment in research and development ensures continuous improvement in extrusion techniques, enhancing profile strength, surface finish, and dimensional accuracy.

Dajcor Aluminum Ltd., based in Chatham, Ontario, is a leading North American supplier of extruded aluminum components. They offer a wide range of conventional standard aluminum profiles along with value-added services such as fabrication, machining, anodizing, and assembly. Dajcor serves multiple industries including automotive, renewable energy, transportation, and architectural sectors.

Their comprehensive capabilities and focus on quality make Dajcor a top choice for customers requiring reliable and precise aluminum profiles. The company's commitment to customer service and flexible production schedules allows them to handle both large-scale and specialized orders efficiently.

Apel Extrusions Ltd., located in Calgary, Alberta, is recognized for its high-performance aluminum extrusion products. With over 45 years of experience, Apel has established itself as an independent aluminum extruder and finisher with state-of-the-art anodizing and fabrication facilities. They produce a broad spectrum of conventional standard aluminum profiles designed for durability and aesthetic appeal.

Apel's commitment to innovation and quality control ensures that their aluminum profiles meet the stringent requirements of various industrial applications. Their in-house finishing capabilities, including anodizing and powder coating, add value by enhancing corrosion resistance and visual appeal.

Alfiniti Inc., situated in Saguenay, Quebec, specializes in drawn aluminum tubes and pipes but also offers custom aluminum extrusions including conventional standard profiles. Known for competitive pricing and innovative solutions, Alfiniti caters to industries such as automotive, medical, and construction. Their expertise in extrusion technology allows them to produce profiles with precise dimensions and excellent surface finishes.

Alfiniti's focus on technological advancement and customer collaboration enables them to develop profiles that meet unique engineering challenges. Their ability to provide both standard and custom profiles makes them a versatile supplier in the Canadian market.

The top conventional standard aluminum profiles manufacturers in Canada supply profiles used in a variety of critical applications:

- Construction: Aluminum profiles are widely used in window and door frames, curtain walls, structural supports, and facades. Their corrosion resistance and lightweight nature make them ideal for modern architectural designs that demand both strength and aesthetic appeal.

- Automotive: The automotive industry benefits from aluminum profiles for lightweight structural components, frames, and body parts. Reducing vehicle weight improves fuel efficiency and lowers emissions, aligning with environmental regulations.

- Aerospace: Aircraft components require materials that offer high strength-to-weight ratios. Conventional aluminum profiles provide the necessary durability while contributing to overall weight reduction, which is crucial for fuel efficiency and performance.

- Renewable Energy: Aluminum profiles form the structural frames for solar panels and wind turbine components. Their resistance to harsh weather conditions and ability to be fabricated into complex shapes make them indispensable in this sector.

- Transportation: Rail and marine vehicle parts utilize aluminum profiles for their strength, corrosion resistance, and ease of fabrication, enhancing safety and longevity.

- Industrial Machinery: Equipment frames, protective guards, and conveyor systems often incorporate aluminum profiles due to their flexibility and durability.

The versatility and strength-to-weight ratio of aluminum profiles make them ideal for these diverse applications, supporting innovation and efficiency across industries.

Choosing Canadian manufacturers for conventional standard aluminum profiles offers several advantages:

- Quality Assurance: Canadian manufacturers adhere to strict quality standards, ensuring durable and reliable products that meet or exceed industry specifications.

- Advanced Technology: The use of modern extrusion and finishing technologies guarantees precision, consistency, and superior surface finishes.

- Customization: Many manufacturers provide tailored solutions, allowing clients to specify dimensions, alloys, and finishes to meet unique project requirements.

- Sustainability: Canadian companies often prioritize environmentally responsible practices, including the use of recycled aluminum, energy-efficient production methods, and waste reduction initiatives.

- Timely Delivery: Proximity to major North American markets enables efficient logistics and supply chain management, reducing lead times and transportation costs.

- Technical Support: Manufacturers offer expert guidance on material selection, design optimization, and finishing options, helping clients achieve the best performance and cost-effectiveness.

These advantages make Canadian manufacturers a reliable choice for businesses seeking high-quality conventional standard aluminum profiles.

The aluminum profile industry in Canada is poised for growth, driven by technological advancements and increasing demand from emerging sectors. Some key trends include:

- Lightweighting Initiatives: As industries strive to reduce carbon footprints, aluminum profiles are increasingly favored for their ability to reduce weight without compromising strength.

- Smart Manufacturing: Integration of automation, robotics, and data analytics in extrusion processes enhances efficiency, quality control, and customization capabilities.

- Sustainable Materials: Growing emphasis on circular economy principles encourages the use of recycled aluminum and environmentally friendly production techniques.

- Innovative Alloys: Development of new aluminum alloys with improved mechanical properties expands the range of applications.

- Collaborative Engineering: Manufacturers work closely with clients to develop profiles that meet specific performance criteria, reducing material waste and improving product lifecycle.

Canadian manufacturers are investing in research and development to stay at the forefront of these trends, ensuring their continued leadership in the conventional standard aluminum profiles market.

The top conventional standard aluminum profiles manufacturers in Canada play a vital role in supporting various industrial sectors by providing high-quality, precision-engineered aluminum profiles. Companies like Almag Aluminum Inc., Exco Technologies Limited, Dajcor Aluminum Ltd., Apel Extrusions Ltd., and Alfiniti Inc. exemplify excellence in manufacturing, innovation, and customer service. Their capabilities in producing conventional standard aluminum profiles enable them to meet the diverse needs of construction, automotive, aerospace, and other industries, contributing significantly to Canada's manufacturing strength and global competitiveness.

With a strong focus on quality, customization, sustainability, and technological advancement, these manufacturers continue to drive growth and innovation in the aluminum extrusion industry. Choosing Canadian manufacturers ensures access to reliable, efficient, and environmentally responsible aluminum profile solutions tailored to meet the evolving demands of modern industries.

Conventional standard aluminum profiles are aluminum extrusions produced using traditional extrusion methods and standardized dimensions to meet common industrial requirements. They are widely used in construction, automotive, aerospace, and other sectors.

Aluminum profiles in Canada are commonly used in construction (windows, doors, facades), automotive (vehicle frames and parts), aerospace (aircraft components), renewable energy (solar panel frames), transportation, and industrial machinery.

Canadian manufacturers stand out due to their adherence to strict quality standards, advanced extrusion technologies, customization capabilities, sustainable manufacturing practices, and efficient supply chain logistics.

Yes, many top Canadian manufacturers offer customized aluminum profiles tailored to specific design and performance needs, supported by in-house die design and fabrication capabilities.

The aluminum extrusion market supports multiple industries, creates jobs, promotes technological innovation, and contributes to exports, thus playing a significant role in Canada's industrial and economic development.

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?

Stainless Steel Sheets Vs Galvanized Steel Sheets: Pros And Cons Compared

Stainless Steel Sheets Vs Aluminum Sheets: Which One Suits Your Project?

Cold Rolled Vs Hot Rolled Stainless Steel Sheets: Key Differences Explained

How To Choose Stainless Steel for Industrial Guardrails And Railings?