English

Views: 222 Author: Tomorrow Publish Time: 2025-07-16 Origin: Site

Content Menu

● Overview of Material Composition

● Corrosion Resistance and Chemical Compatibility

● Temperature and Pressure Considerations

● Installation and Maintenance

● Environmental and Health Considerations

● Widening Applications for Both Materials

● Frequently Asked Questions (FAQ)

>> 1. What are the main differences between stainless steel pipes and PVC pipes?

>> 2. Which pipe material is better for hot water supply?

>> 3. Are PVC pipes resistant to corrosion?

>> 4. How does the cost of stainless steel pipes compare to PVC pipes?

>> 5. Which pipe type is more environmentally friendly?

When deciding between stainless steel pipes and PVC pipes for piping and plumbing projects, understanding the differences between these two materials is essential. Each has unique properties that make it better suited for specific environments and applications. This comprehensive article explores the strengths, weaknesses, and practical considerations for stainless steel and PVC pipes to guide your choice.

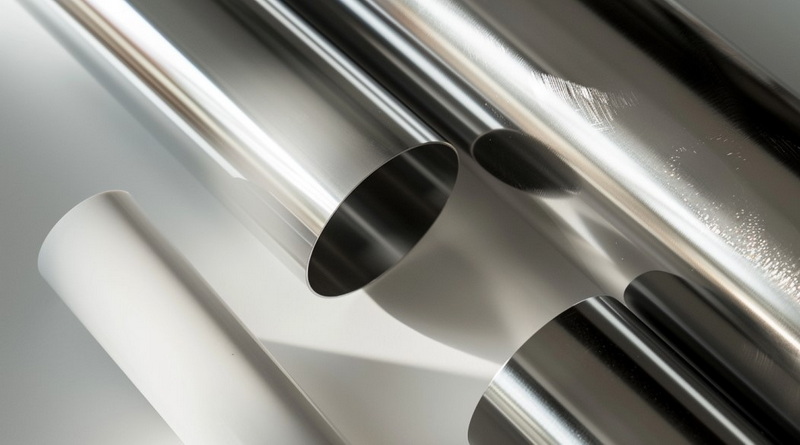

Stainless steel pipes are made from an alloy consisting primarily of steel combined with chromium, often with nickel and other elements that enhance corrosion resistance and durability. The two most common grades are 304 and 316 stainless steel, valued for their strength and ability to resist corrosion even under demanding conditions. Stainless steel's metal composition delivers not only robustness but also an attractive surface finish, making it a preferred choice in environments where both functionality and aesthetics are important.

PVC pipes, or polyvinyl chloride pipes, are plastic-based and lightweight. They are widely used for residential plumbing, irrigation, and drainage systems because of their chemical resistance, ease of installation, and cost advantage. PVC was introduced as a cost-effective alternative to metal piping and has gained extensive popularity due to its versatility. PVC pipes are produced in various schedules and sizes, enabling use in a broad range of pressure and flow applications.

One of the most significant differences between stainless steel and PVC pipes lies in their mechanical strength. Stainless steel pipes exhibit dramatically higher tensile strength — approximately four times that of copper pipes and up to 8–10 times that of plastic pipes. This makes stainless steel pipes inherently more robust under impact, pressure, and external forces. They are capable of withstanding high internal pressures and external mechanical stresses without deforming or cracking. This characteristic is particularly important in industrial, oil, and gas applications, where durability is critical for safety and efficiency.

PVC pipes, while durable for plastic materials, cannot match the structural integrity of stainless steel. They are prone to cracking or breaking under extreme pressure or impact and are less suitable for heavy-duty or industrial environments. Although PVC is tough against abrasion and chemical attacks, its vulnerability to physical damage limits its use in some applications where robust mechanical properties are necessary. Over time, environmental stress cracking can also degrade PVC pipe strength, especially when subjected to repeated hydraulic stresses.

Stainless steel is often described as a "corrosion-less" material due to its passive chromium oxide layer that self-heals and prevents ongoing rusting. While stainless steel resists most forms of corrosion well, certain acids and chlorides can attack it over time. The 316-grade stainless steel contains molybdenum, which improves resistance to chlorides, making it suitable for marine or chemical environments. However, prolonged exposure to aggressive chemicals or environments can cause pitting or crevice corrosion.

PVC, on the other hand, is a non-corrosive material that resists many chemical substances inherently, making it ideal for handling acids and many industrial chemicals that may corrode metal pipes. This chemical inertness extends to alkalis and salts, allowing PVC pipes to be used in water treatment plants, chemical processing, and sewage systems. Furthermore, PVC does not rust or support microbiological growth as readily as stainless steel, which can be an advantage in certain water applications where biofilm formation is a concern.

Stainless steel pipes can tolerate a broad range of operating temperatures and pressures. They maintain structural integrity under high temperature, high pressure, and varying thermal conditions, making them suitable for hot water supply, steam, and industrial fluid transport. Stainless steel pipelines can work efficiently up to temperatures exceeding several hundred degrees Celsius without losing strength or becoming brittle. Their low thermal expansion coefficient ensures dimensional stability in fluctuating temperatures.

PVC pipes have lower thermal tolerance; they can deform or degrade at higher temperatures and generally are rated for lower pressure systems compared to stainless steel. The typical maximum operating temperature for PVC is below one hundred degrees Celsius, which limits its use in exposure to hot liquids or steam. The thermal expansion of PVC is also significantly higher, which can result in joint stress and leakage, particularly in concealed or outdoor installations where temperature changes are frequent. Engineers must carefully consider these limits during design to prevent premature joint failures.

PVC pipes are lightweight and flexible, making installation simpler, faster, and less labor-intensive. They use solvent cement or mechanical joints that do not require welding or special fittings. This ease of installation reduces labor costs and onsite complexity. PVC also allows for easier modifications or routing changes and requires less heavy equipment for handling and cutting.

Stainless steel pipes are heavier and require skilled labor for welding, threading, or clamping connections. The installation process is more complex and time-consuming but results in a highly reliable and durable system. Proper welding ensures leak-proof joints that can withstand high pressures and corrosive environments. The requirements for skilled welders and quality control inspections increase the installation cost but greatly extend the lifecycle of the piping system.

Maintenance-wise, stainless steel pipelines require less frequent inspection in harsh environments thanks to their robustness. They also tend to accumulate less scale and deposits, which helps preserve flow capacity. PVC systems, while resistant to many chemicals, may require more regular monitoring for leaks, especially in high-stress or fluctuating temperature applications. Over time, UV exposure can degrade PVC in outdoor settings unless UV-resistant variants are used or protective coatings applied.

PVC pipes are significantly more affordable both in initial material cost and installation expenses. This cost advantage makes them popular for residential and budget-constrained projects. The lower weight and simple joining methods reduce labor and equipment costs. PVC's widespread availability and ease of customization with different fittings and sizes also contribute to its economic appeal.

Stainless steel pipes demand a higher upfront investment, often costing multiple times more than PVC. However, their long service life, durability, and low maintenance needs can make them cost-effective over the long term, especially in industrial or harsh environments. The resistance to fire, temperature extremes, and corrosion means stainless steel pipelines often require fewer replacements or repairs, offsetting initial expense.

Stainless steel is recyclable and environmentally friendly. It does not degrade or leach harmful chemicals into the environment, making it a sustainable choice in many scenarios. The durability of stainless steel also reduces waste by extending the lifecycle of piping systems. Recycling stainless steel requires less energy compared to producing new alloy, which helps reduce carbon footprint.

PVC, while resistant to corrosion, is a plastic that can release toxic chemicals if burned or improperly disposed of. Its production involves the use of chlorine and additives which can have negative environmental impacts. Limitations in recycling affect PVC's environmental footprint, as it is less frequently recycled and often ends up in landfills. Innovations in PVC recycling and bio-based plastics aim to improve its sustainability, but concerns remain.

Stainless steel pipes have expanded use beyond traditional industrial and commercial plumbing into architectural applications, food and beverage sanitation, pharmaceutical piping, and even medical instrumentation where hygiene and chemical purity are critical. Their smooth surface finish and resistance to bio-contaminants make them ideal for these specialized uses.

PVC pipes continue to evolve with new formulations offering improved UV resistance, flexibility, and strength. These enhancements have expanded their use in underground utilities, agricultural irrigation, and sewer systems. Some PVC variants are now certified safe for potable water, increasing their appeal in residential plumbing globally.

| Feature | Stainless Steel Pipes | PVC Pipes |

|---|---|---|

| Material Type | Metal alloy (steel, chromium, nickel) | Plastic (polyvinyl chloride) |

| Strength & Durability | Very high, withstands pressure & impact | Moderate, susceptible to breaking |

| Corrosion Resistance | Excellent but susceptible to some acids | Excellent against many chemicals |

| Temperature Tolerance | High, suitable for hot fluids | Low to moderate |

| Thermal Expansion | Low | High |

| Installation | Complex, requires skilled labor | Easy and fast |

| Cost | High initial cost | Low initial cost |

| Environmental Impact | Recyclable, sustainable | Less eco-friendly, difficult recycling |

| Maintenance | Low | Higher maintenance needs |

Choosing between stainless steel and PVC pipes depends largely on your specific application, budget, and environmental considerations. Stainless steel pipes offer unmatched strength, durability, and temperature resistance, ideal for industrial, high-pressure, and long-term applications. PVC pipes provide a cost-effective, corrosion-resistant, and easy-to-install alternative for residential plumbing, chemical handling, and low-pressure uses.

For projects demanding longevity, robustness, and exposure to harsh environments, stainless steel is the superior choice. For everyday household plumbing, agricultural irrigation, or chemical drainage where budget constraints are present, PVC pipes remain a practical and reliable option. Consulting with professionals and carefully assessing your system requirements will ensure the best material choice.

Stainless steel pipes are metal alloys that provide higher strength, durability, and temperature resistance, while PVC pipes are plastic, lightweight, and more cost-effective but less strong and less tolerant of heat.

Stainless steel pipes are better suited for hot water systems due to their high thermal tolerance and strength. PVC pipes may deform or fail under high temperatures.

Yes, PVC pipes are inherently resistant to many chemical agents and do not rust, making them highly corrosion-resistant, especially against acids.

Stainless steel pipes cost significantly more initially—often up to five times the cost of PVC. However, they offer better long-term value in demanding environments.

Stainless steel pipes are more environmentally friendly due to their recyclability and non-toxic material composition, while PVC pipes pose concerns related to production energy use and disposal toxicity.

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?

Stainless Steel 430 Vs 304: Key Differences Explained for Manufacturers

304 Vs 316 Stainless Steel Grades: Which One Suits Your Project Best?

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?