English

Views: 222 Author: Tomorrow Publish Time: 2025-07-17 Origin: Site

Content Menu

● What Are Austenitic and Martensitic Stainless Steels?

>> Martensitic Stainless Steel

● Chemical Composition Differences

● Mechanical Properties and Heat Treatment

● Fabrication and Welding Characteristics

● Magnetic Properties and Implications

>> Austenitic Stainless Steel Common Uses

>> Martensitic Stainless Steel Common Uses

● Advantages and Disadvantages

● Selection Criteria: Which to Choose?

● FAQ About Austenitic and Martensitic Stainless Steel

>> 1. What is the main microstructural difference between austenitic and martensitic stainless steel?

>> 2. Can martensitic stainless steel be used in highly corrosive environments?

>> 3. Why is austenitic stainless steel generally non-magnetic and martensitic magnetic?

>> 4. Which stainless steel type is easier to weld and fabricate?

>> 5. What are common applications for martensitic stainless steel?

Stainless steel is a fundamental material widely used across various industries due to its durability and resistance to corrosion. Among its many types, Austenitic and Martensitic stainless steels stand out as two primary classes with distinct properties, microstructures, and applications. This article provides an in-depth comparison of these two stainless steel categories, emphasizing their composition, characteristics, advantages, disadvantages, and typical uses, helping professionals make informed material choices.

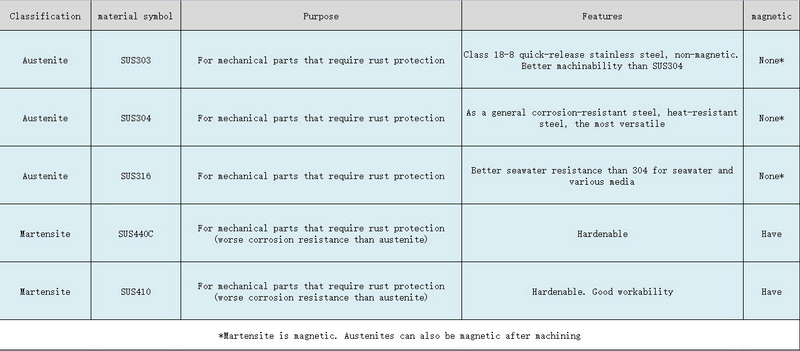

Austenitic stainless steel is defined by its face-centered cubic (FCC) crystal structure and high levels of chromium (16-26%) and nickel (6-22%), sometimes with additional elements such as manganese or nitrogen. This unique microstructure imparts excellent corrosion resistance, ductility, and formability. Austenitic steels are generally non-magnetic and are among the most commonly used stainless steels due to their versatility and superior corrosion resistance.

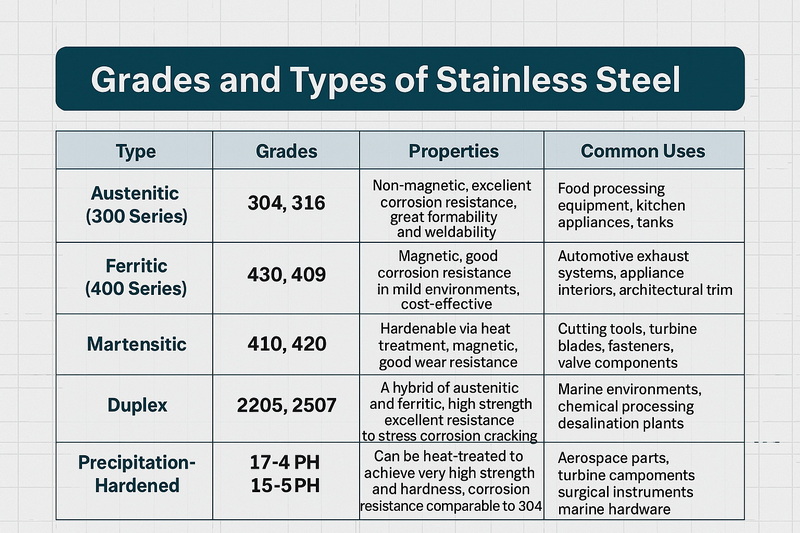

Key Grades: 304, 316, 321, and 200 series grades (which contain nitrogen for added strength).

Martensitic stainless steels feature a body-centered tetragonal (BCT) crystal structure, relying on chromium (11.5-18%) and higher carbon content (0.1-1.2%) with little or no nickel. The carbon content allows for heat treatment, which significantly increases hardness and strength but usually reduces corrosion resistance. Martensitic steels are magnetic and are known for their excellent wear resistance, strength, and ability to be hardened.

Key Grades: 410, 420, 440, and 431.

| Component | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Chromium (Cr) | 16-26% | 11.5-18% |

| Nickel (Ni) | 6-22% | Generally minimal or absent |

| Carbon (C) | Very low (<0.1%) | Higher (0.1-1.2%) |

| Other Elements | Nitrogen, Manganese, Molybdenum | Sometimes small additions of other elements |

This compositional difference directly affects microstructure and thus mechanical and corrosion properties.

| Property | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Crystal Structure | Face-centered cubic (FCC) | Body-centered tetragonal (BCT) |

| Corrosion Resistance | Excellent; superior for harsh environments | Moderate to low; prone to corrosion in some situations |

| Strength | Moderate to high; can be work hardened | Very high; can be heat treated for maximum strength |

| Hardness | Lower; not hardenable by heat treatment | High; hardenable through heat treatment |

| Ductility | Very high; excellent formability | Lower; less ductile |

| Weldability | Excellent; easier to weld | Difficult; needs careful control to avoid brittleness |

| Magnetic Behavior | Generally non-magnetic | Magnetic |

| Oxidation Resistance | Good at high temperatures | Limited high temperature use |

Austenitic stainless steels exhibit good toughness and strength at a wide range of temperatures but cannot be hardened through heat treatment, relying instead on work hardening (cold working). They show excellent ductility, making them ideal for applications requiring shaping or forming.

Martensitic steels, in contrast, develop hardness through quenching and tempering. Heat treatment processes transform their microstructure to martensite, yielding hardened and wear-resistant material suitable for tools and mechanical parts requiring durability and strength.

The heat treatment process for martensitic steels involves heating the steel to a temperature where the structure becomes austenitic, then rapidly cooling it (quenching) to form martensite, which is very hard but brittle. A tempering step follows to relieve stresses and improve toughness without significantly sacrificing hardness. This treatment process gives martensitic stainless steel its characteristic high strength and wear resistance.

The chromium and nickel content in austenitic stainless steels provides a continuous protective oxide layer, granting superior corrosion resistance even in aggressive environments like chemical processing, marine settings, and food industries. Nickel helps stabilize the austenitic phase, enhancing corrosion resistance and toughness.

Martensitic steels have lower chromium content and higher carbon, which reduce their corrosion resistance, making them less suitable for harsh or highly corrosive environments. However, in moderate conditions, certain grades like AISI 431 offer a balance of corrosion resistance and strength. Proper surface treatments such as passivation or coatings can improve corrosion resistance, but martensitic steels still do not match the corrosion performance of austenitic grades.

Austenitic stainless steel is well known for its excellent weldability and formability. Because of its high ductility and stable microstructure, it can be shaped into complex forms without cracking. Welding techniques commonly include TIG, MIG, and spot welding, with minimal precautions needed to maintain mechanical properties.

Conversely, martensitic stainless steel poses challenges in both fabrication and welding due to its high carbon content. Without careful heat control, welding can cause cracking, loss of toughness, or unwanted phase changes that impair strength. Preheating before welding and post-weld heat treatments are often necessary to avoid brittleness and maintain mechanical integrity. Machining martensitic steels also requires more rigid tooling and controlled conditions because of their increased hardness.

The magnetic nature of stainless steel types has practical consequences. Austenitic stainless steel's generally non-magnetic character is preferred in electronic and medical applications where magnetism could interfere with equipment or cause undesirable effects.

Martensitic stainless steel's magnetic properties make it useful in applications requiring magnetic responsiveness or where magnetic permeability is advantageous, such as magnetic clamps or sensors. However, the presence of magnetism can also be a disadvantage where non-magnetic materials are mandated.

Austenitic stainless steels commonly cost more due to the high nickel content, a more expensive alloying element. The processing costs, such as welding and cold working, tend to be moderate owing to their superior formability.

Martensitic stainless steels are often less expensive in raw material terms but may incur higher fabrication costs due to heat treatment and welding complexities. The choice between these two types often balances upfront material price against lifecycle costs impacted by durability and processing.

- Food processing equipment, where hygienic surfaces and resistance to acidic foods are critical

- Chemical tanks and reactors exposed to corrosive environments

- Architectural and structural components where corrosion resistance and aesthetic finish are important

- Medical devices and implants benefiting from non-magnetism and biocompatibility

- Kitchenware and cookware

- Automotive trim and exhaust systems

- Heat exchangers and furnace components needing oxidation resistance

- Cutlery such as knives and scissors, emphasizing edge retention and hardness

- Surgical instruments requiring sharpness and strength

- Bearings, valve parts, and pump shafts subjected to wear and mechanical stress

- Springs, fasteners, and blades where high tensile strength is essential

- Aerospace and automotive components needing a combination of strength and moderate corrosion resistance

- Marine hardware where mechanical strength is prioritized over corrosion resistance

| Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|

| Advantages | |

| Superior corrosion resistance | Higher hardness and strength via heat treatment |

| Excellent ductility and formability | Good wear resistance |

| Non-magnetic and easy to weld | Magnetic, enabling specific mechanical design benefits |

| Performs well at cryogenic temperatures | Can be precisely heat-treated for tailored mechanical properties |

| Disadvantages | |

| Lower strength compared to martensitic types | Lower corrosion resistance |

| Cannot be hardened by heat treatment | Difficult to weld and less ductile |

| Generally more expensive due to higher nickel content | Susceptible to corrosion if not properly alloyed or treated |

Choosing between austenitic and martensitic stainless steel depends on your application's demands:

- If corrosion resistance, formability, and weldability are critical, austenitic steel is the preferred choice.

- If you require high strength, hardness, and wear resistance, with moderate corrosion resistance sufficing, martensitic steel is ideal.

- Consider mechanical environment, exposure to corrosive agents, manufacturing processes, and cost parameters when making the decision.

Some industries opt for a mixed approach, employing austenitic stainless steel where corrosion protection is paramount and martensitic steel for components requiring high mechanical strength.

| Characteristic | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Common Grades | 304, 316, 321, 200 series | 410, 420, 440, 431 |

| Corrosion Resistance | Excellent | Moderate to low |

| Strength | Moderate | Very high (after heat treatment) |

| Hardness | Lower | High |

| Ductility | Very high | Low |

| Magnetism | Generally non-magnetic | Magnetic |

| Heat Treatable | No | Yes |

| Weldability | Excellent | Difficult |

| Typical Applications | Food, chemical, medical, architecture | Cutlery, surgical tools, springs, valves |

In summary, Austenitic and Martensitic stainless steels serve distinct purposes due to their fundamental differences in composition and structure. Austenitic stainless steels excel in corrosion resistance, ductility, and toughness, making them suitable for environments requiring long-term durability and formability. Conversely, martensitic stainless steels provide superior hardness and strength through heat treatment, fitting applications demanding wear resistance and mechanical toughness but with reduced corrosion resistance.

Understanding these distinctions ensures optimized material selection, which enhances performance, longevity, and cost-efficiency across various industrial and technological applications.

Austenitic stainless steel has a face-centered cubic (FCC) structure, offering excellent corrosion resistance and ductility, while martensitic stainless steel has a body-centered tetragonal (BCT) structure, allowing heat-treatment hardening for high strength and hardness.

Martensitic stainless steel has inferior corrosion resistance compared to austenitic grades. It is suited for moderate corrosion environments; high-corrosion applications generally require austenitic steels.

The FCC structure of austenitic steel causes it to be non-magnetic, whereas the BCT martensite structure inherently exhibits magnetic properties due to the arrangement of iron atoms.

Austenitic stainless steel is easier to weld and fabricate due to its ductility and lower carbon content. Martensitic stainless steel requires specialized welding techniques to prevent brittleness.

Martensitic steel is widely used for cutlery, surgical instruments, valve parts, springs, and mechanical components requiring high hardness and wear resistance.

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?

Stainless Steel 430 Vs 304: Key Differences Explained for Manufacturers

304 Vs 316 Stainless Steel Grades: Which One Suits Your Project Best?

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?