English

Views: 222 Author: Tomorrow Publish Time: 2025-07-13 Origin: Site

Content Menu

● What Is A Modular Aluminum Profile?

● Features of Modular Aluminum Profiles

● How Modular Aluminum Profiles Are Used

>> Industrial Automation and Machinery

>> Workstations and Ergonomic Systems

>> Transportation and Vehicle Construction

>> Architectural and Display Systems

>> Robotics and Research Equipment

>> Custom Machinery and Prototyping

>> Cleanroom and Laboratory Environments

● Advantages of Modular Aluminum Profiles

● FAQ

>> 1. What materials are modular aluminum profiles typically made from?

>> 2. How are modular aluminum profiles connected?

>> 3. Can modular aluminum profiles be customized?

>> 4. What industries benefit most from modular aluminum profiles?

>> 5. What surface treatments are available for modular aluminum profiles?

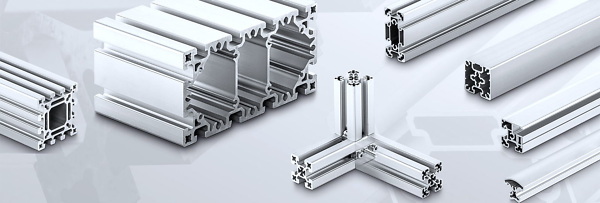

A modular aluminum profile is a specially designed aluminum extrusion that follows a modular system principle, allowing standardized dimensions and shapes to be combined flexibly. These profiles are widely used in various industries due to their versatility, lightweight nature, strength, and ease of assembly. This article explores what modular aluminum profiles are, their features, applications, and advantages.

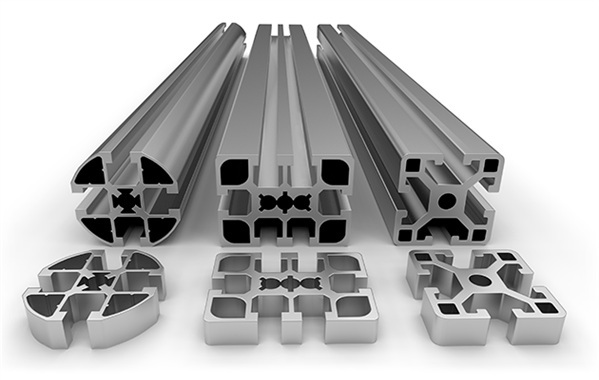

A modular aluminum profile is an aluminum extrusion that is manufactured with standardized dimensions and shapes to enable easy combination and assembly into complex structures. The modularity concept means that profiles can be connected using compatible components without the need for extensive machining or customization. These profiles are typically made from high-quality aluminum alloys such as 6060, 6061, or 6082, which provide excellent mechanical strength, corrosion resistance, and lightweight properties.

The profiles often feature grooves or slots that allow for the insertion of connectors, fasteners, and other assembly elements, making them highly adaptable for different configurations. The dimensional tolerances are precise, usually within +/- 0.15 mm, ensuring interchangeability and reliability in industrial applications.

- Standardized Dimensions and Shapes: Profiles come in various standard sizes such as 30x30 mm, 45x45 mm, and 90x90 mm, enabling compatibility across different components.

- High-Quality Alloy Composition: Alloys like 6060 and 6063 are common, offering excellent resistance to corrosion, shocks, and environmental factors.

- Lightweight and Strong: Aluminum's strength-to-weight ratio makes these profiles ideal for structures requiring durability without excessive weight.

- Versatile Connection Systems: Grooves and slots in the profiles allow easy assembly with nuts, bolts, connectors, and specialized fittings.

- Low Maintenance: Aluminum's corrosion resistance reduces the need for upkeep, making it suitable for long-term use.

- Customizable Surface Treatments: Profiles can be anodized, powder-coated, polished, or otherwise treated to improve aesthetics and durability.

- Recyclability: Aluminum is highly recyclable, making modular aluminum profiles an environmentally friendly choice in sustainable manufacturing.

Modular aluminum profiles are fundamental in building frames, machine guards, conveyor systems, and automation equipment. Their modular nature allows engineers to design and assemble complex machinery structures quickly and adapt them as needed without extensive retooling. For example, in automated production lines, modular aluminum profiles provide a flexible framework to mount sensors, actuators, and control panels, enabling rapid customization and scalability.

They are widely used to create adjustable workbenches, ergonomic workplace systems, and assembly lines. The profiles' modularity makes it easy to customize height, dimensions, and accessories to suit different operator needs. This adaptability improves worker comfort and productivity by allowing quick adjustments to workstation layouts and configurations.

Due to their light weight and strength, modular aluminum profiles are used in vehicle frames, racks, and supports. Their corrosion resistance is beneficial for outdoor and harsh environment applications. In electric vehicle manufacturing, for example, these profiles help reduce overall vehicle weight, improving energy efficiency and range.

Modular aluminum profiles are employed in building glass display cabinets, exhibition stands, and architectural frameworks. Their clean appearance combined with structural integrity makes them popular in commercial and retail settings. The profiles allow for easy assembly and disassembly of exhibition booths and retail displays, facilitating rapid setup and teardown for events.

The profiles provide a flexible and reliable framework for mounting sensors, cameras, robotic arms, and other research instruments. Their ease of assembly and reconfiguration supports iterative development. Laboratories and research institutions benefit from modular aluminum profiles by creating adaptable test rigs and experimental setups that can evolve with ongoing projects.

Modular aluminum profiles are ideal for prototyping new machines and equipment. Their modularity allows designers to build and modify prototypes rapidly without the need for welding or permanent fixtures. This accelerates product development cycles and reduces costs.

In environments where cleanliness and contamination control are critical, modular aluminum profiles are used to build cleanroom furniture, partitions, and equipment frames. Aluminum's non-corrosive surface and ability to be anodized for smooth finishes make it suitable for these sensitive applications.

- Ease of Assembly: Components can be quickly connected using standard fasteners without the need for welding or complex machining. This reduces assembly time and labor costs.

- Flexibility: Profiles can be combined and reassembled into different configurations, supporting prototyping and modular system growth. This flexibility is invaluable in industries where requirements frequently change.

- Durability: High-quality aluminum alloys provide resistance to corrosion, wear, and mechanical stress, ensuring long service life even in demanding environments.

- Cost-Effectiveness: Reduced machining and maintenance costs make modular aluminum profiles economical over their lifecycle. The ability to reuse components also contributes to cost savings.

- Lightweight: The low density of aluminum reduces overall system weight, improving portability and reducing structural load.

- Compatibility: Standardized grooves and dimensions ensure components from different manufacturers can be integrated seamlessly, fostering a broad ecosystem of compatible accessories.

- Aesthetic Appeal: The clean lines and surface finishes possible with modular aluminum profiles make them suitable for visible architectural and commercial applications.

- Sustainability: Aluminum's recyclability and the profiles' long lifespan contribute to environmentally responsible manufacturing and design.

A modular aluminum profile is a versatile, lightweight, and strong structural element designed with standardized dimensions and shapes to enable easy assembly and customization. Its widespread use across industries such as automation, transportation, architecture, and research underscores its importance as a fundamental building block for modern engineering and manufacturing. The modular design principle ensures flexibility, cost-effectiveness, and durability, making modular aluminum profiles an essential component in contemporary industrial applications.

Whether constructing complex machinery frames, ergonomic workstations, vehicle supports, or architectural displays, modular aluminum profiles offer unmatched adaptability and efficiency. Their ease of assembly, combined with excellent mechanical properties and environmental benefits, positions them as a preferred choice for engineers, designers, and manufacturers worldwide.

Modular aluminum profiles are usually made from high-quality aluminum alloys such as 6060, 6061, and 6082, which provide excellent mechanical strength and corrosion resistance.

They are connected using compatible fasteners, nuts, bolts, and specialized connectors that fit into the profile's grooves or slots, allowing tool-free or minimal-tool assembly.

Yes, while standard sizes and shapes are common, special modular aluminum profiles with unique dimensions and features can be manufactured to meet specific technical requirements.

Industries including industrial automation, mechanical engineering, transportation, architecture, and research benefit from the flexibility and durability of modular aluminum profiles.

Common surface treatments include anodizing, powder coating, polishing, and painting, which enhance corrosion resistance, appearance, and wear resistance.

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?

Stainless Steel Sheets Vs Galvanized Steel Sheets: Pros And Cons Compared

Stainless Steel Sheets Vs Aluminum Sheets: Which One Suits Your Project?

Cold Rolled Vs Hot Rolled Stainless Steel Sheets: Key Differences Explained

How To Choose Stainless Steel for Industrial Guardrails And Railings?