English

Views: 222 Author: Tomorrow Publish Time: 2025-07-10 Origin: Site

Content Menu

● Understanding Aluminum Profiles

● Key Properties of Aluminum Profiles

● Manufacturing Process of Aluminum Profiles

● Applications of Aluminum Profiles

>> 1. Construction and Architecture

>> 3. Industrial Equipment and Manufacturing

>> 4. Electronics and Electrical Applications

● Advantages of Using Aluminum Profiles

● FAQ

>> 1. What materials are used to make aluminum profiles?

>> 2. How are aluminum profiles manufactured?

>> 3. What industries commonly use aluminum profiles?

>> 4. Why are aluminum profiles preferred over steel in construction?

>> 5. Can aluminum profiles be recycled?

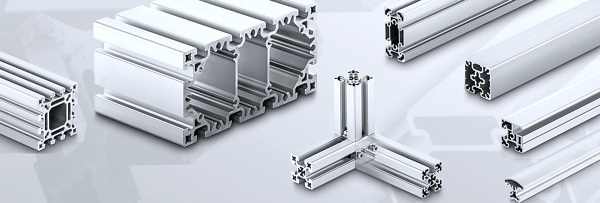

Aluminum profiles are versatile, extruded aluminum products shaped into various cross-sectional forms to meet diverse industrial and architectural needs. They are created by heating aluminum alloys and forcing them through molds, resulting in lightweight, strong, and corrosion-resistant components widely used across many sectors. This article explores what aluminum profiles are, their properties, manufacturing processes, and the extensive ways they are utilized in modern industry and construction.

An aluminum profile is essentially an aluminum alloy that has been extruded into a specific shape or cross-section. The extrusion process allows for the creation of complex shapes with consistent dimensions, which can be customized for particular applications. Aluminum profiles come in many forms, including solid, hollow, architectural, and custom profiles, each designed to fulfill unique functional and aesthetic requirements.

The base material, aluminum, is a lightweight metal known for its excellent corrosion resistance, machinability, and strength-to-weight ratio. When alloyed with elements such as magnesium and silicon, aluminum profiles gain enhanced mechanical properties, making them suitable for demanding environments.

- Lightweight: Aluminum has a density roughly one-third that of steel or copper, reducing the overall weight of structures and components.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making aluminum profiles ideal for outdoor and harsh environments.

- Strength and Durability: Alloyed aluminum profiles offer excellent strength while maintaining flexibility and formability.

- Machinability: Aluminum profiles can be easily cut, drilled, milled, or joined, allowing for versatile fabrication.

- Thermal and Electrical Conductivity: Aluminum profiles conduct heat and electricity efficiently, useful in power and electronic applications.

- Environmental Sustainability: Aluminum is highly recyclable without loss of properties, supporting eco-friendly manufacturing.

The production of aluminum profiles involves several steps:

1. Alloy Selection: Choosing the appropriate aluminum alloy based on required strength, corrosion resistance, and machinability.

2. Melting and Casting: Aluminum alloy is melted and cast into billets.

3. Extrusion: The billet is heated and pushed through a die to form the desired profile shape.

4. Heat Treatment: Profiles may undergo aging or annealing to enhance mechanical properties.

5. Surface Treatment: Anodizing, powder coating, or painting improves corrosion resistance and aesthetics.

6. Cutting and Finishing: Profiles are cut to length and machined as needed for specific applications.

The extrusion process is highly flexible, allowing manufacturers to create profiles with intricate designs and precise tolerances. This adaptability makes aluminum profiles suitable for a wide range of applications, from structural components to decorative elements.

The versatility of aluminum profiles makes them indispensable in various industries, including construction, transportation, electronics, power, and manufacturing.

Aluminum profiles are extensively used in building frameworks, curtain walls, window and door frames, roofing systems, and interior partitions. Their corrosion resistance and lightweight nature make them ideal for modern high-rise buildings and large-span structures. Aluminum profiles also serve as decorative panels, railings, and structural supports, contributing to both the aesthetics and durability of buildings.

In addition to structural uses, aluminum profiles are favored for their thermal insulation properties when combined with thermal breaks. This helps improve energy efficiency in buildings, reducing heating and cooling costs. The ability to anodize or powder-coat aluminum profiles also allows architects to choose from a wide range of colors and finishes, enhancing design flexibility.

In automotive, railway, and aerospace sectors, aluminum profiles help reduce vehicle weight, improving fuel efficiency and performance. They are used in chassis, body panels, railings, and structural components of trains, buses, and ships. The lightweight yet strong nature of aluminum profiles supports safer and more energy-efficient transportation solutions.

Moreover, aluminum profiles contribute to noise and vibration reduction in vehicles, enhancing passenger comfort. Their corrosion resistance is especially valuable in marine environments, where exposure to saltwater can quickly degrade other metals.

Aluminum profiles form the backbone of many industrial machines and assembly lines. They are used to build conveyor systems, machine frames, guards, workstations, and storage racks. The modularity of aluminum profiles allows manufacturers to quickly reconfigure layouts, enhancing productivity and flexibility.

The ease of assembly and disassembly of aluminum profile systems also supports lean manufacturing principles, reducing downtime and facilitating maintenance. Additionally, aluminum profiles can be integrated with other materials such as plastics or rubber to provide customized solutions for specific industrial challenges.

Due to their excellent thermal and electrical conductivity, aluminum profiles are used in heat sinks, busbars, enclosures, and cable trays. They help dissipate heat in electronic devices and provide structural support for electrical systems, improving reliability and efficiency.

Aluminum profiles also play a crucial role in renewable energy technologies. For example, they are used in the frames of solar panels, providing lightweight and durable support structures that withstand environmental stresses.

Aluminum profiles are vital in power transmission lines, substations, and energy storage systems. Their use in conductors and ground wires enhances conductivity while reducing weight. Additionally, aluminum profiles are employed in transmission towers and battery racks, contributing to more efficient and durable power infrastructure.

Their corrosion resistance and strength make aluminum profiles ideal for outdoor power installations exposed to harsh weather. Furthermore, aluminum's recyclability aligns with the growing emphasis on sustainable energy solutions.

Custom aluminum profiles are tailored to specific needs in medical equipment, furniture, nautical construction, kitchen equipment, and storage tanks. The ability to design unique shapes and sizes allows for innovative solutions across diverse industries.

For instance, in medical device manufacturing, aluminum profiles provide lightweight yet sturdy frameworks that can be sterilized easily. In furniture design, aluminum profiles enable sleek, modern aesthetics combined with durability.

- Cost-Effective: Aluminum profiles reduce material and transportation costs due to their light weight.

- Design Flexibility: Extrusion allows for complex shapes that meet precise engineering needs.

- Longevity: Resistance to corrosion and weathering ensures long service life.

- Sustainability: Aluminum's recyclability supports environmental goals.

- Ease of Assembly: Profiles can be joined using various methods, facilitating quick and efficient construction.

- Thermal Efficiency: Aluminum profiles can be designed with thermal breaks to improve insulation.

- Low Maintenance: Aluminum profiles require minimal upkeep compared to other metals.

Aluminum profiles are fundamental components in modern industry and construction, valued for their lightweight, strength, corrosion resistance, and versatility. Their wide-ranging applications—from building structures and transportation to electronics and power systems—demonstrate their indispensable role in advancing technology and infrastructure. As industries continue to seek sustainable, efficient, and durable materials, aluminum profiles will remain a critical solution for innovative design and engineering challenges.

Aluminum profiles are primarily made from aluminum alloys, often including magnesium and silicon, to enhance strength and corrosion resistance while maintaining lightweight characteristics.

They are produced by heating aluminum alloy billets and extruding them through shaped dies, followed by heat treatment and surface finishing processes such as anodizing or powder coating.

Key industries include construction, transportation (automotive, railway, aerospace), electronics, power transmission, manufacturing, and custom applications like medical equipment and furniture.

Aluminum profiles offer a lighter weight, excellent corrosion resistance, and easier machinability, which contribute to faster construction, reduced structural loads, and longer-lasting buildings.

Yes, aluminum profiles are highly recyclable without losing their properties, making them an environmentally friendly choice for sustainable manufacturing and construction.

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?

Stainless Steel Sheets Vs Galvanized Steel Sheets: Pros And Cons Compared

Stainless Steel Sheets Vs Aluminum Sheets: Which One Suits Your Project?

Cold Rolled Vs Hot Rolled Stainless Steel Sheets: Key Differences Explained

How To Choose Stainless Steel for Industrial Guardrails And Railings?