English

Views: 222 Author: Tomorrow Publish Time: 2025-07-04 Origin: Site

Content Menu

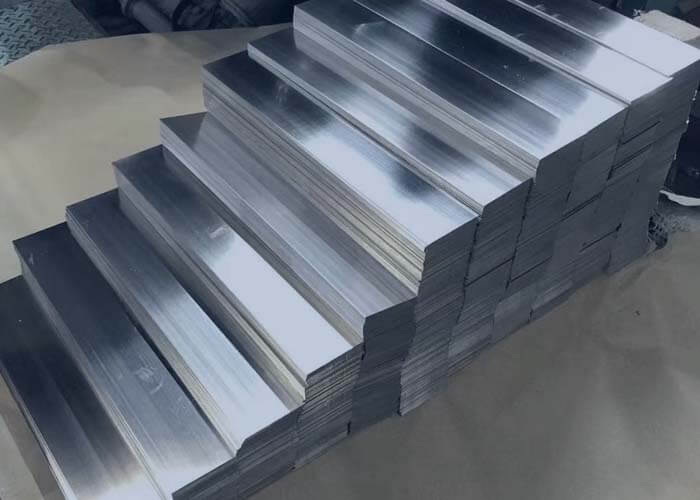

● Understanding the Material: A 5 mm Thick Stainless Steel Strip

● Is It Easy to Cut a 5 mm Thick Stainless Steel Strip?

● Best Tools and Methods to Cut a 5 mm Thick Stainless Steel Strip

>> 1. Angle Grinder with a Cutting Disc

>> 2. Circular Saw with a Carbide-Tipped Blade

>> 3. Band Saw

● Practical Tips for Cutting a 5 mm Thick Stainless Steel Strip

● Additional Considerations When Cutting a 5 mm Thick Stainless Steel Strip

>> Heat Generation and Its Effects

>> Environmental and Workplace Factors

>> Cost and Accessibility of Cutting Methods

● FAQ

>> 1. What is the easiest tool to cut a 5 mm thick stainless steel strip?

>> 2. Can I cut a 5 mm thick stainless steel strip with tin snips?

>> 3. Is laser cutting suitable for a 5 mm thick stainless steel strip?

>> 4. How can I avoid warping when cutting a 5 mm thick stainless steel strip?

>> 5. What finishing steps are necessary after cutting a 5 mm thick stainless steel strip?

Cutting a 5 mm thick stainless steel strip is a common task in metalworking, fabrication, and various industrial applications. However, stainless steel's toughness, corrosion resistance, and hardness make it a challenging material to cut cleanly and efficiently. This article explores the feasibility of cutting a 5 mm thick stainless steel strip, the best tools and methods to use, and practical tips to achieve precise and safe cuts.

A 5 mm thick stainless steel strip is a moderately thick piece of metal that requires careful handling during cutting. Stainless steel is an alloy known for its durability, resistance to rust, and strength. These properties make it ideal for many applications but also mean that cutting it demands tools capable of handling its toughness without damaging the strip or the cutting equipment.

The thickness of 5 mm places this strip beyond the range of very thin sheets, which can often be cut with simple hand tools, but not so thick as to require industrial heavy machinery exclusively. This thickness is common in structural components, decorative strips, and precision parts, where maintaining edge quality and dimensional accuracy is important.

Stainless steel comes in various grades, each with slightly different cutting characteristics. For example, austenitic stainless steels are tougher and more ductile, while martensitic grades are harder but more brittle. Knowing the exact grade of the 5 mm thick stainless steel strip can influence the choice of cutting method and tools.

Cutting a 5 mm thick stainless steel strip is *not* as straightforward as cutting thinner metals or softer materials. It is certainly possible, but the ease depends on the cutting method, tools, and operator skill.

- Manual cutting with basic hand tools like tin snips or scissors is generally *not* feasible for 5 mm thickness due to the metal's hardness and thickness.

- Power tools such as angle grinders, circular saws with metal-cutting blades, and band saws are more appropriate and can cut through 5 mm strips with relative ease.

- Precision cutting methods like laser cutting, water jet cutting, or CNC milling offer clean, accurate cuts but require specialized equipment.

In summary, while a 5 mm thick stainless steel strip can be cut, it requires the right tools and techniques to do so effectively without damaging the material or tools.

An angle grinder equipped with a metal cutting disc is one of the most accessible and versatile tools for cutting a 5 mm thick stainless steel strip. It allows for fast, rough cuts and is suitable for straight or curved lines.

- Use a disc rated specifically for stainless steel.

- Secure the strip firmly before cutting.

- Apply light, steady pressure to avoid overheating or warping the material.

- Expect some burrs that will need to be deburred or filed afterward.

Angle grinders are portable and relatively inexpensive, making them popular for on-site work or smaller fabrication shops. However, controlling the cut line precisely can be challenging, so practice and steady hands are important.

A circular saw fitted with a carbide-tipped blade designed for metal cutting can produce cleaner and more precise cuts on a 5 mm thick stainless steel strip.

- Use a blade with a high tooth count (10–14 teeth per inch).

- Cut slowly to avoid blade damage and overheating.

- Clamp the strip securely to prevent movement.

Circular saws offer better control than angle grinders and are suitable for longer straight cuts. They are commonly used in fabrication shops and by professional metalworkers.

For thicker or longer strips, a band saw with a metal cutting blade is effective. It provides good control and can handle continuous cutting.

- Choose a blade suitable for stainless steel.

- Maintain a steady feed rate.

- Ideal for straight cuts.

Band saws reduce the risk of overheating and produce relatively smooth edges, which reduces finishing time. They are especially useful for batch cutting multiple strips.

Laser cutting is a high-precision method suitable for 5 mm thick stainless steel strips. It produces clean edges with minimal heat distortion.

- Requires access to a laser cutting machine.

- Ideal for complex shapes and tight tolerances.

- Faster and more precise but more expensive.

Laser cutting uses a focused beam of light to melt or vaporize the metal along the cut line. It is widely used in industries requiring high precision and minimal post-processing.

Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut stainless steel.

- No heat is generated, so no thermal distortion.

- Suitable for thick strips like 5 mm stainless steel.

- Provides smooth edges and high precision.

Water jet cutting is environmentally friendly and versatile, capable of cutting a wide range of materials with minimal kerf width.

Plasma cutting can handle thick stainless steel strips but is generally more suited for thicker plates than 5 mm strips.

- Produces fast cuts.

- May require finishing to smooth edges.

Plasma cutters use ionized gas to melt the metal. While effective, they can create rough edges and heat-affected zones that require additional finishing.

- Safety First: Always wear safety goggles, gloves, and hearing protection.

- Secure the Strip: Use clamps or a vise to hold the strip firmly to prevent movement.

- Mark the Cut Line: Use a permanent marker or scribe to clearly define where to cut.

- Use Cooling or Lubrication: Applying cutting fluid or coolant helps reduce heat buildup and prolongs tool life.

- Deburr Edges: After cutting, use a file or deburring tool to smooth sharp edges and remove burrs.

- Cut Slowly and Steadily: Rushing can cause tool damage, poor cuts, or warping.

- Choose the Right Blade or Disc: Using blades or discs specifically designed for stainless steel improves cut quality and tool longevity.

- Maintain Tools: Keep cutting tools sharp and clean to ensure efficient cutting and reduce heat generation.

- Consider Material Stress: Stainless steel can harden when cut quickly or improperly; slow, controlled cuts minimize this effect.

Cutting stainless steel generates significant heat, especially with power tools. Excessive heat can cause warping, discoloration, and changes in the metal's microstructure, potentially weakening the strip. Using cooling methods such as water sprays, cutting fluids, or pauses during cutting can help dissipate heat.

The quality of the cut edge on a 5 mm thick stainless steel strip is crucial in many applications. Rough or jagged edges can cause assembly issues, safety hazards, or corrosion points. Post-cut finishing such as grinding, sanding, or polishing is often necessary to achieve the desired surface quality.

Cutting stainless steel produces metal dust and sparks, which require proper ventilation and safety measures. Noise levels can be high with power tools, so hearing protection is essential. Additionally, proper disposal of metal scraps and used cutting fluids should be considered to minimize environmental impact.

While laser and water jet cutting provide excellent results, they require specialized equipment that may not be accessible to all users. Angle grinders and circular saws are more affordable and widely available but may require more manual effort and finishing work. Balancing cost, precision, and availability is key when deciding how to cut a 5 mm thick stainless steel strip.

A 5 mm thick stainless steel strip can be cut effectively, but it is not an easy task without the right tools and techniques. Manual cutting methods are generally insufficient for this thickness. Power tools such as angle grinders, circular saws, and band saws are practical for most users, while laser and water jet cutting offer superior precision and edge quality for industrial applications. Proper preparation, safety measures, and finishing work are essential to achieve clean, accurate cuts on stainless steel strips of this thickness. Understanding the material properties, managing heat, and selecting appropriate cutting methods will ensure successful and efficient cutting of a 5 mm thick stainless steel strip.

The easiest tool for most users is an angle grinder with a stainless steel cutting disc. It is versatile, widely available, and effective for cutting 5 mm thick strips.

No, tin snips are not suitable for cutting a 5 mm thick stainless steel strip because the material is too thick and hard for manual snips to handle.

Yes, laser cutting is highly suitable for 5 mm thick stainless steel strips, offering precision and clean edges, though it requires specialized equipment.

To avoid warping, cut slowly with proper cooling or lubrication and secure the strip firmly to minimize vibrations and heat buildup.

After cutting, deburr the edges using a file or deburring tool to remove sharp burrs and ensure safe handling and proper fit.

Seven Requirements for External Doors And Windows of Passive Rooms

How Much Do You Know about The Design Standards for Aluminum Alloy Door And Window Dimensions?

Welding Vs Stainless Steel Fabrication: Understanding The Manufacturing Process Differences

Stainless Steel Fabrication Vs Powder Coated Steel: Durability And Cost Comparison

CNC Machining Vs Stainless Steel Fabrication: Pros And Cons for Industrial Use

Stainless Steel Fabrication Vs Carbon Steel Fabrication: Key Differences Explained

Stainless Steel Fabrication Vs Aluminum Fabrication: Which Is Right for Your Project?

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?