English

Views: 222 Author: Tomorrow Publish Time: 2025-06-30 Origin: Site

Content Menu

● Overview of Aluminum Flat Tubes

● Leading Aluminum Flat Tube Manufacturers and Suppliers in France

>> 2. MCB

>> 3. Aluminiumwerk Unna AG (Germany-based with European Reach)

>> 4. Prosaic Steel and Alloys

>> 5. French Local Manufacturers (Trade Data Insights)

● Applications of Aluminum Flat Tubes in France

>> OEM Services

● Advantages of Aluminum Flat Tubes

● Quality Control and Industry Standards

● Innovations and Trends in Aluminum Flat Tube Manufacturing

● Frequently Asked Questions (FAQs)

>> Q1: What alloys are commonly used for aluminum flat tubes?

>> Q2: Can aluminum flat tubes be customized in size and finish?

>> Q3: Are there OEM services available for aluminum flat tubes in France?

>> Q4: What industries use aluminum flat tubes the most?

>> Q5: How does the extrusion process affect aluminum tube quality?

Aluminum flat tubes are essential components widely used in construction, automotive, aerospace, and furniture industries due to their lightweight, strength, and corrosion resistance. France hosts a number of leading manufacturers and suppliers of aluminum flat tubes who provide high-quality products and customized OEM services to global clients. This article explores the top aluminum flat tube manufacturers and suppliers in France, highlighting their capabilities, product ranges, industry applications, and the benefits of choosing aluminum flat tubes for various projects.

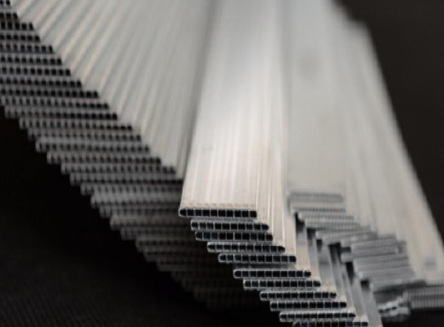

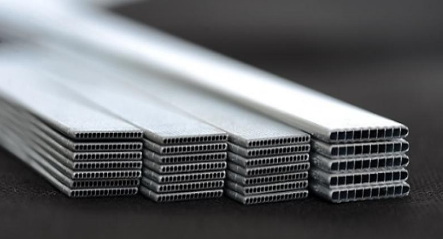

Aluminum flat tubes are extruded profiles with a rectangular or square cross-section, offering excellent mechanical properties and versatility. They are favored for applications requiring lightweight yet durable materials, such as door and window frames, aluminum railings, curtain walls, and full aluminum furniture. The tubes can be customized in terms of alloy composition, temper, surface finish, and dimensions to meet specific engineering requirements.

The manufacturing process typically involves extrusion, where heated aluminum billets are forced through a shaped die to create the desired tube profile. Post-extrusion treatments such as aging (heat treatment), anodizing, and powder coating enhance the mechanical properties and surface durability of the tubes. This combination of processes ensures that aluminum flat tubes meet stringent quality standards required by demanding industries.

LODEC Group is a prominent supplier of high-quality aluminum tubes catering to construction, automotive, and aerospace sectors. Their aluminum tubes range in outer diameter from 6 mm to 250 mm, with wall thicknesses from 0.5 mm to 20 mm, and standard lengths of 3000 mm or 6000 mm. They offer alloys such as 6061 and 6082 with temper options T5 and T6. Surface finishes include mill finish, anodized, and powder-coated options. LODEC emphasizes performance, reliability, and flexible financing solutions to streamline customer operations.

LODEC's commitment to innovation is evident in their investment in advanced extrusion technology and quality control systems. They also provide comprehensive OEM services, enabling foreign brands and wholesalers to receive tailor-made aluminum flat tubes that meet their exact specifications. Their ability to combine technical expertise with customer service has made them a trusted partner in the European aluminum industry.

MCB is a notable aluminum tube supplier in Europe, including France, offering various profiles such as round, square, and rectangular tubes made from EN AW-6060 T66 alloy. Although their web portal is under maintenance, MCB is known for its quality aluminum tubes suited for diverse industrial applications.

MCB's product portfolio includes tubes with precise dimensional tolerances and excellent surface finishes, making them ideal for architectural and industrial applications. They also focus on sustainable manufacturing practices, minimizing waste and energy consumption throughout their production processes.

While based in Germany, Aluminiumwerk Unna AG supplies aluminum tubes across Europe, including France. They specialize in seamless and porthole extrusion methods, producing tubes with diameters ranging from 11 mm to 355 mm. Their expertise in extrusion technology ensures precision and durability in aluminum tubes, making them a preferred supplier for French manufacturers.

Their seamless extrusion process produces tubes with superior mechanical properties and uniform wall thickness, which is crucial for structural applications in aerospace and automotive industries. Aluminiumwerk Unna AG also offers extensive customization options, including special alloys and heat treatments.

Prosaic Steel and Alloys supplies high-grade aluminum tubes with excellent strength-to-weight ratios, corrosion resistance, and dimensional accuracy. They provide tubes in various alloys such as 6060, 6063, and 6065 with temper options including T4, T5, and T6. Surface treatments include anodizing, powder coating, and polishing, catering to both industrial and decorative uses.

Their customer-centric approach includes technical support for design optimization and logistics services to ensure timely delivery. Prosaic Steel and Alloys also actively collaborates with clients to develop innovative aluminum solutions that meet evolving market demands.

Trade data shows several active aluminum tube manufacturers and suppliers in France, located in regions such as Poissy, Boulogne-Billancourt, Paris, and Thoissey. These companies handle significant shipment volumes and serve both domestic and international markets, indicating a robust aluminum tube manufacturing sector in France.

Many of these local manufacturers specialize in niche markets such as architectural aluminum systems, bespoke furniture components, and industrial machinery parts. Their proximity to major industrial hubs allows them to provide quick turnaround times and personalized service.

Aluminum flat tubes are widely used in door and window frames, curtain walls, and architectural railings due to their durability and aesthetic appeal. The lightweight nature of aluminum reduces the structural load on buildings, allowing architects greater freedom in design. Additionally, aluminum's corrosion resistance ensures long-term performance even in harsh weather conditions.

Full aluminum furniture and decorative aluminum profiles benefit from flat tubes for their lightweight and corrosion resistance. Aluminum flat tubes enable the creation of sleek, modern designs that are both sturdy and easy to maintain. The ability to anodize or powder coat these tubes in various colors adds to their versatility in interior design.

Aluminum tubes provide structural components that reduce vehicle weight and improve fuel efficiency. In the automotive sector, aluminum flat tubes are used in chassis, frames, and body components. Aerospace applications demand tubes with high strength-to-weight ratios and tight tolerances, which French manufacturers are well-equipped to supply.

Many French manufacturers offer OEM services, producing aluminum flat tubes tailored to the specifications of foreign brands, wholesalers, and producers. This enables international companies to leverage France's advanced manufacturing capabilities while maintaining control over product design and quality.

Aluminum flat tubes provide excellent strength-to-weight ratios, making them ideal for structural applications where reducing weight is critical without compromising strength.

Aluminum naturally forms a protective oxide layer, enhancing durability in outdoor and humid environments. This reduces maintenance costs and extends product lifespan.

Options like anodizing and powder coating allow customization for both functional and decorative purposes, improving aesthetics and surface hardness.

Manufacturers can produce tubes in various sizes and thicknesses to meet diverse engineering needs, from thin-walled decorative profiles to thick structural components.

Aluminum is recyclable, supporting eco-friendly manufacturing practices. Many manufacturers in France incorporate recycled aluminum into their production, reducing environmental impact.

While aluminum may have a higher initial cost compared to some materials, its longevity, low maintenance, and lightweight properties contribute to overall cost savings in many applications.

French aluminum flat tube manufacturers adhere to rigorous quality control protocols and comply with European standards such as EN 755 and EN 12020. These standards specify mechanical properties, dimensional tolerances, and surface quality requirements to ensure product reliability.

Manufacturers employ advanced testing methods including tensile strength tests, hardness measurements, and non-destructive testing to detect surface defects or internal flaws. This commitment to quality ensures that aluminum flat tubes meet the demanding needs of industries like aerospace and automotive, where safety and performance are paramount.

The aluminum industry in France is embracing innovations such as:

- Advanced Extrusion Techniques: Improved die design and temperature control enhance tube precision and surface finish.

- Hybrid Materials: Combining aluminum with composites to create tubes with enhanced strength and reduced weight.

- Smart Manufacturing: Integration of Industry 4.0 technologies like IoT sensors and AI-driven quality control for real-time monitoring.

- Sustainable Practices: Increased use of recycled aluminum and energy-efficient production methods to reduce carbon footprint.

- Customization and Rapid Prototyping: Use of 3D modeling and additive manufacturing to accelerate product development and meet bespoke client needs.

These trends position French aluminum flat tube manufacturers at the forefront of global competitiveness.

France hosts a dynamic and technologically advanced aluminum flat tube manufacturing sector, serving diverse industries with high-quality and customizable products. Leading companies such as LODEC Group, MCB, Aluminiumwerk Unna AG, and Prosaic Steel and Alloys provide a wide range of aluminum flat tubes with various alloys, finishes, and dimensions. These manufacturers not only meet domestic demand but also offer OEM services to international clients, reinforcing France's position as a key player in the aluminum extrusion market.

The combination of advanced production techniques, material expertise, and customer-centric services ensures that aluminum flat tube suppliers in France continue to deliver durable, lightweight, and aesthetically pleasing solutions for modern engineering challenges. With ongoing innovations and a strong commitment to sustainability, the French aluminum flat tube industry is well-positioned for future growth and global competitiveness.

A1: Common alloys include 6061, 6063, 6060, and 6082, chosen for their strength, corrosion resistance, and workability.

A2: Yes, manufacturers offer a range of dimensions, wall thicknesses, and surface finishes such as anodizing, powder coating, and polishing.

A3: Yes, many French manufacturers provide OEM services, producing aluminum flat tubes tailored to client specifications for global brands and wholesalers.

A4: Construction, automotive, aerospace, and furniture industries are the primary users of aluminum flat tubes due to their versatile properties.

A5: Extrusion methods like seamless and porthole extrusion influence tube strength, surface quality, and dimensional accuracy, impacting overall performance.

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?

Stainless Steel 430 Vs 304: Key Differences Explained for Manufacturers

304 Vs 316 Stainless Steel Grades: Which One Suits Your Project Best?

Stainless Steel Pipes Vs Galvanized Pipes: Durability And Cost Analysis

Comparing Stainless Steel Pipes And PVC Pipes: What You Need To Know?

Stainless Steel Pipes Vs Copper Pipes: Pros And Cons for Industrial Use

Seamless Stainless Steel Pipes Vs Welded Pipes: Key Differences Explained

Stainless Steel Pipes Vs Carbon Steel Pipes: Which One Suits Your Project?