English

Views: 222 Author: Tomorrow Publish Time: 2025-06-29 Origin: Site

Content Menu

● Overview of Aluminum Square Tubes

● Material Characteristics and Alloy Selection

● Top Aluminum Square Tube Manufacturers and Suppliers in Canada

>> 1. Diversified Specialty Metals

● Industry Applications and Benefits

>> Construction and Architecture

>> Industrial Equipment and Machinery

● Customization and Technical Support

● Quality Standards and Certifications

● Environmental Considerations

● Frequently Asked Questions (FAQs)

>> Q1: What alloys are commonly used for aluminum square tubes in Canada?

>> Q2: Can aluminum square tubes be custom sized?

>> Q3: Are aluminum square tubes suitable for welding?

>> Q4: What industries use aluminum square tubes the most?

>> Q5: How does the finish affect aluminum square tubes?

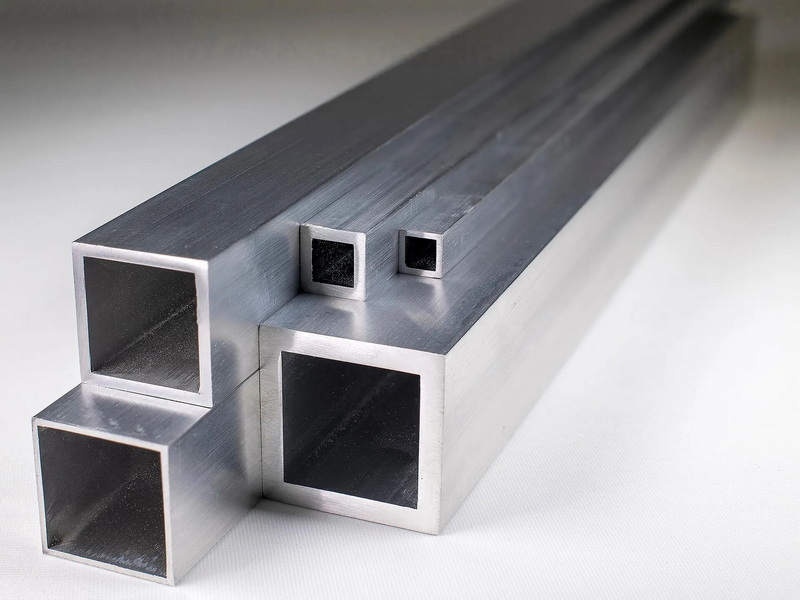

Aluminum square tubes are essential components in various industries, including construction, automotive, aerospace, and home decor. Their lightweight, corrosion resistance, and strength make them ideal for structural and ornamental applications. Canada hosts several top manufacturers and suppliers specializing in aluminum square tubes, offering a wide range of sizes, finishes, and alloys to meet diverse engineering and design needs. This article explores the leading aluminum square tube manufacturers and suppliers in Canada, highlighting their product offerings, capabilities, and industry applications.

Aluminum square tubes are hollow extrusions with a square cross-section, commonly made from alloys such as 6061 and 6063. They are prized for their:

- Strength-to-weight ratio: Strong yet lightweight, making them easy to handle and install.

- Corrosion resistance: Aluminum naturally forms a protective oxide layer, preventing rust.

- Machinability and weldability: Suitable for various fabrication methods including welding and brazing.

- Versatility: Used in aerospace, automotive, architectural, and furniture applications.

The tubes come in different corner styles such as sharp or rounded corners, various thicknesses, and lengths, typically 8 to 24 feet, to suit specific project requirements.

Choosing the right alloy and temper for aluminum square tubes is crucial to meet the demands of different applications. The most common alloys used in Canada are:

- 6061 Aluminum Alloy: Known for its excellent mechanical properties, corrosion resistance, and weldability. It is often supplied in T6 or T651 tempers, providing high strength and good machinability. This alloy is widely used in structural applications and aerospace components.

- 6063 Aluminum Alloy: Often referred to as an architectural alloy, 6063 offers excellent surface finish and corrosion resistance, making it ideal for ornamental and architectural uses. It is typically supplied in T5 or T52 tempers and is easier to extrude compared to 6061.

The choice between these alloys depends on the desired balance between strength, finish, and fabrication requirements.

Aluminum square tubes are produced primarily through extrusion, where heated aluminum billets are forced through a die to create the hollow square cross-section. After extrusion, the tubes undergo processes such as:

- Aging and heat treatment: To achieve desired mechanical properties.

- Cutting and sizing: To standard or custom lengths.

- Surface finishing: Including mill finish, anodizing, powder coating, or painting to enhance corrosion resistance and aesthetics.

- Quality inspection: Ensuring dimensional accuracy, surface integrity, and mechanical properties meet industry standards.

Canadian manufacturers invest in state-of-the-art extrusion presses and finishing equipment to maintain high quality and consistency.

Diversified Specialty Metals is a leading Canadian distributor and service center for aluminum square tubes. They offer an extensive catalog of aluminum square tubes in 6061 alloy with T6 and T651 tempers, available in both sharp and rounded corners. Their product dimensions range from 0.75" square tubes to 4" square tubes with wall thicknesses from 0.095" to 0.250". They provide mill finish tubes and can accommodate custom sizes to meet specialized needs.

Their facilities in Ontario and Québec cover over 150,000 square feet, enabling them to serve both Canadian and U.S. manufacturers with fast turnaround and delivery. Metallurgists and product specialists support customers to ensure quality and technical compliance.

Product Examples:

| Size (Square) | Thickness | Temper | Finish |

|---|---|---|---|

| 1" x 0.120" | 0.120" | T651 | Mill Finish |

| 2" x 0.250" | 0.250" | T651 | Mill Finish |

| 3" x 0.188" | 0.188" | T651 | Mill Finish |

Millennium Alloys specializes in square tube shaped metals, offering 6061-T6 aluminum square tubes with round corners. Their online platform allows for easy ordering and customization. Prices are competitive, and they cater to both small and large quantity orders.

Steel Depot supplies aluminum square tubes widely used in aerospace and aviation industries due to their strength and weldability. They emphasize the corrosion resistance of aluminum square tubes, which develop a protective passivating layer. Their tubes are known for smooth texture and uniform surface, making them suitable for high durability applications.

Russel Metals offers 6063-T5 aluminum square tubing with sharp corners, ideal for ornamental work due to its excellent finishing and fair machinability. Their tubing is easily welded and is popular among manufacturers requiring aesthetic and structural qualities.

Metals Supermarkets is the world's largest small-quantity metal supplier, providing aluminum square tubing cut to size. They prioritize customer convenience by offering custom cuts and fast delivery, serving a broad range of industries from construction to manufacturing.

Aluminum square tubes find applications across a wide spectrum of industries due to their unique properties:

In construction, aluminum square tubes are used for structural frameworks, curtain walls, window frames, and decorative railings. Their corrosion resistance ensures longevity in outdoor environments, while their lightweight nature reduces structural load and installation costs. Aluminum's recyclability also supports sustainable building practices.

The automotive and aerospace sectors benefit from aluminum square tubes for their excellent strength-to-weight ratio. They are used in vehicle frames, supports, and components where reducing weight improves fuel efficiency and performance. Aerospace-grade aluminum square tubes undergo stringent quality control to meet safety and durability standards.

Aluminum square tubes are popular in furniture manufacturing for frames of chairs, tables, shelving units, and cabinetry. Their sleek appearance, combined with powder coating or anodized finishes, allows designers to create modern, durable, and lightweight furniture pieces.

In industrial settings, aluminum square tubes serve as machine guards, conveyor frames, and fabrication components. Their machinability enables customization to specific equipment needs, while corrosion resistance reduces maintenance.

Many Canadian manufacturers and suppliers provide tailored solutions beyond standard sizes and alloys. Custom cutting, punching, drilling, and finishing services are common. Technical support teams assist customers in selecting the right alloy, temper, and dimensions for their specific projects, ensuring compliance with industry standards such as ASTM B221.

Leading aluminum square tube manufacturers in Canada adhere to rigorous quality standards. Certifications may include:

- ISO 9001: Quality management systems.

- ASTM B221: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes.

- RoHS Compliance: Ensuring materials are free from hazardous substances.

Such certifications guarantee that products meet or exceed customer and regulatory expectations.

Aluminum is highly recyclable, and many Canadian manufacturers emphasize sustainability by using recycled content and energy-efficient production methods. This reduces environmental impact and supports green building certifications such as LEED.

Canada boasts a robust market of aluminum square tube manufacturers and suppliers, offering high-quality products tailored to diverse industrial needs. Companies like Diversified Specialty Metals, Millennium Alloys, Steel Depot, Russel Metals, and Metals Supermarkets provide extensive product ranges, customization options, and technical support. Aluminum square tubes' versatility, strength, and corrosion resistance make them indispensable in construction, aerospace, automotive, and decorative applications. Choosing the right supplier ensures access to premium materials and expert guidance, facilitating successful project outcomes.

A1: The most common alloys are 6061 and 6063, known for their strength, corrosion resistance, and machinability.

A2: Yes, most Canadian suppliers offer custom sizes and thicknesses to meet specific project requirements.

A3: Yes, aluminum square tubes are highly weldable using various welding techniques, making them ideal for structural applications.

A4: Key industries include aerospace, automotive, construction, architecture, and furniture manufacturing.

A5: Finishes like mill finish provide a natural protective layer, while anodizing or painting can enhance corrosion resistance and aesthetics.

Seven Requirements for External Doors And Windows of Passive Rooms

How Much Do You Know about The Design Standards for Aluminum Alloy Door And Window Dimensions?

Welding Vs Stainless Steel Fabrication: Understanding The Manufacturing Process Differences

Stainless Steel Fabrication Vs Powder Coated Steel: Durability And Cost Comparison

CNC Machining Vs Stainless Steel Fabrication: Pros And Cons for Industrial Use

Stainless Steel Fabrication Vs Carbon Steel Fabrication: Key Differences Explained

Stainless Steel Fabrication Vs Aluminum Fabrication: Which Is Right for Your Project?

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?