English

Views: 222 Author: Tomorrow Publish Time: 2025-06-28 Origin: Site

Content Menu

● Overview of Aluminum Square Tubes

>> Key Characteristics of Aluminum Square Tubes

● Leading Aluminum Square Tube Manufacturers and Suppliers in France

>> 2. Hydro Aluminium Toulouse

>> 3. Aluminium Fabrication Diffusion

>> 5. Metric Metal (International Supplier with French Market Reach)

● Applications of Aluminum Square Tubes in France

● Advantages of Choosing French Aluminum Square Tube Manufacturers

● Industry Trends and Innovations

● Frequently Asked Questions (FAQs)

>> Q1: What are the common aluminum alloys used for square tubes in France?

>> Q2: Can French manufacturers provide custom sizes and finishes?

>> Q3: Are aluminum square tubes recyclable?

>> Q4: What industries in France use aluminum square tubes the most?

>> Q5: How do I choose the right aluminum square tube supplier in France?

Aluminum square tubes are essential components widely used in construction, automotive, aerospace, furniture, and industrial applications. France, with its strong industrial base and advanced manufacturing capabilities, hosts several leading aluminum square tube manufacturers and suppliers. This article explores the top aluminum square tube manufacturers and suppliers in France, highlighting their products, services, and industry contributions. It also provides insights into the aluminum square tube market, key features, and frequently asked questions.

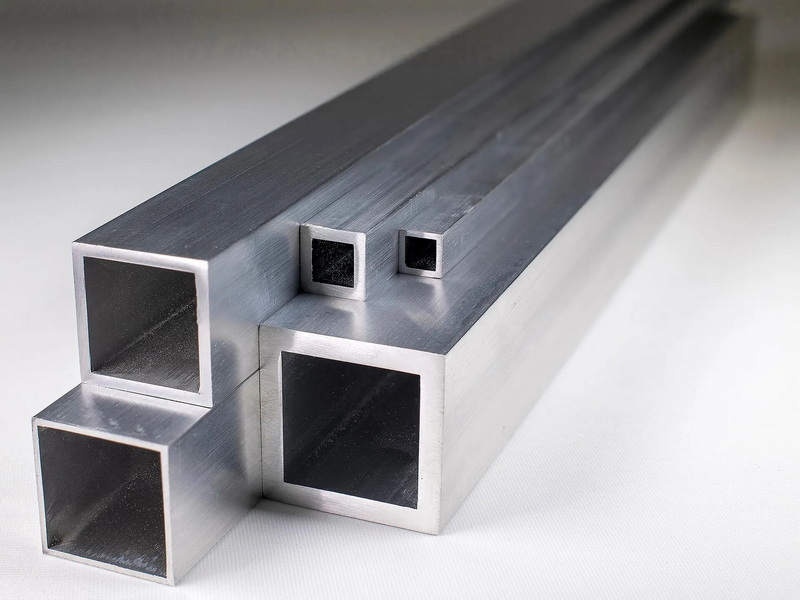

Aluminum square tubes are hollow structural sections with a square cross-section made from aluminum alloys. They are prized for their lightweight, corrosion resistance, high strength-to-weight ratio, and excellent machinability. These tubes are used in architectural frameworks, protective railings, furniture, automotive parts, and machinery components.

- Material Grades: Commonly used alloys include 6060, 6061, and 7075, each offering different strength and corrosion resistance levels.

- Dimensions: Available in various sizes, thicknesses, and lengths to meet specific project requirements.

- Finishes: Options include anodized, powder-coated, or mill finish for aesthetic appeal and enhanced durability.

- Applications: Structural support, frames, fencing, automation equipment, and decorative elements.

Located in Saint Vulbas, ETIC Tubes et Profiles has been a specialist in tube drawing since 1995. They offer precision aluminum square tubes with additional capabilities such as cutting, machining, deburring, bending, brazing, and heat treatments. Their expertise serves diverse industries including aerospace, automotive, and construction.

- Specialties: Precision tube drawing, machining, and finishing.

- Industries Served: Aerospace, defense, automotive, furniture, and renewable energy.

- Capabilities: Custom tube profiles and secondary processing.

Hydro Aluminium Toulouse manufactures aluminum parts from sheets and extruded profiles, including square tubes. Their products cater to military, aerospace, electronics, sports equipment, and building sectors.

- Focus Areas: High-quality aluminum parts and profiles.

- Product Range: Extruded aluminum square tubes, sheets, and machined components.

- Market: International, with emphasis on high-performance applications.

Based in La Chatre, this company produces aluminum joinery and square tubes for construction and renovation markets. They emphasize ready-to-install products distributed nationwide.

- Core Products: Aluminum joinery, window frames, and square tubes.

- Customer Base: Dealers, professionals, and construction companies.

- Service: Custom fabrication and installation-ready solutions.

Operating since 1995, ESPACE ALUMINIUM manufactures aluminum joinery and square tubes, focusing on new builds and renovation projects across France.

- Product Offering: Ready-to-install aluminum joinery and profiles.

- Distribution: Nationwide dealer network.

- Specialization: Custom aluminum solutions for residential and commercial buildings.

Though not based in France, Metric Metal supplies high-quality aluminum square tubes to the French market, offering a wide range of grades, sizes, and alloys to meet various industrial needs.

- Product Range: Aluminum square tubes in multiple alloys and dimensions.

- Quality Standards: Industry-leading specifications.

- Customer Support: Tailored solutions for OEM and wholesale clients.

Aluminum square tubes are integral to many sectors in France, including:

- Construction: Frameworks for windows, doors, curtain walls, and protective railings.

- Furniture: Lightweight and durable frames for indoor and outdoor furniture.

- Automotive and Aerospace: Structural components requiring strength and lightness.

- Industrial Equipment: Machine frames, conveyor systems, and automation parts.

- Renewable Energy: Support structures for solar panels and wind turbines.

These applications benefit from aluminum square tubes' combination of strength, corrosion resistance, and ease of fabrication. For example, in construction, aluminum square tubes are often used for curtain wall framing systems due to their ability to support glass panels while maintaining a sleek aesthetic. In furniture design, the tubes provide a modern, minimalist look without compromising durability.

- High Precision and Quality: French manufacturers adhere to strict quality standards and certifications such as ISO 9001 and EN 755, ensuring products meet rigorous performance criteria.

- Customization: Ability to produce tubes tailored to specific dimensions, alloys, and finishes, enabling clients to meet unique project requirements.

- Advanced Technology: Use of modern extrusion, CNC machining, and finishing technologies allows for tight tolerances and complex profiles.

- Sustainability: Commitment to environmentally friendly production, including recycling aluminum scrap and reducing energy consumption.

- Comprehensive Services: From design and engineering consultation to production, finishing, and delivery, manufacturers offer end-to-end solutions.

- Strong OEM Support: Many manufacturers provide OEM services for foreign brands, supporting international trade and supply chain integration.

The aluminum square tube market in France is evolving with several notable trends:

- Lightweight Construction: Increasing demand in automotive and aerospace sectors for lightweight materials to improve fuel efficiency and reduce emissions.

- Enhanced Surface Treatments: Innovations in anodizing and powder coating improve corrosion resistance and aesthetic options.

- Smart Manufacturing: Integration of Industry 4.0 technologies such as IoT sensors and automation for better quality control and production efficiency.

- Recycling and Circular Economy: Growing emphasis on aluminum recycling aligns with European environmental directives, making aluminum square tubes a sustainable choice.

- Hybrid Materials: Combining aluminum tubes with composites or other metals to achieve enhanced mechanical properties.

France boasts a robust network of aluminum square tube manufacturers and suppliers known for their precision, quality, and innovation. Companies like ETIC Tubes et Profiles, Hydro Aluminium Toulouse, and Aluminium Fabrication Diffusion exemplify the country's expertise in producing high-grade aluminum square tubes tailored to diverse industrial needs. Whether for construction, aerospace, or furniture, French manufacturers provide reliable, customizable, and sustainable aluminum square tube solutions. Leveraging advanced technology and comprehensive services, these suppliers continue to meet the evolving demands of both domestic and international markets. With a strong focus on quality, customization, and environmental responsibility, France remains a key player in the global aluminum square tube industry.

A1: The most common alloys are 6060, 6061, and 7075, offering a balance of strength, corrosion resistance, and machinability.

A2: Yes, most manufacturers offer customization in dimensions, thickness, and surface treatments such as anodizing or powder coating.

A3: Absolutely. Aluminum is highly recyclable without loss of quality, supporting sustainable manufacturing practices.

A4: Key industries include construction, automotive, aerospace, furniture manufacturing, and industrial automation.

A5: Consider factors such as product quality, customization options, delivery capabilities, certifications, and after-sales support.

Seven Requirements for External Doors And Windows of Passive Rooms

How Much Do You Know about The Design Standards for Aluminum Alloy Door And Window Dimensions?

Welding Vs Stainless Steel Fabrication: Understanding The Manufacturing Process Differences

Stainless Steel Fabrication Vs Powder Coated Steel: Durability And Cost Comparison

CNC Machining Vs Stainless Steel Fabrication: Pros And Cons for Industrial Use

Stainless Steel Fabrication Vs Carbon Steel Fabrication: Key Differences Explained

Stainless Steel Fabrication Vs Aluminum Fabrication: Which Is Right for Your Project?

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?