English

Views: 222 Author: Tomorrow Publish Time: 2025-06-28 Origin: Site

Content Menu

● Overview of Aluminum Square Tubes

>> Why Choose Aluminum Square Tubes?

● Leading Aluminum Square Tube Manufacturers and Suppliers in the UK

>> 3. Metals4U

>> 5. Metalex

● Applications of Aluminum Square Tubes

● Manufacturing Process of Aluminum Square Tubes

● Advantages of Working with UK Manufacturers and Suppliers

● Frequently Asked Questions (FAQs)

>> Q1: What grades of aluminum are commonly used for square tubes?

>> Q2: Can aluminum square tubes be powder coated?

>> Q3: What are the standard sizes available for aluminum square tubes in the UK?

>> Q4: Do suppliers offer custom cutting services?

>> Q5: What industries commonly use aluminum square tubes?

>> Q6: How does aluminum square tube compare to steel in terms of strength?

>> Q7: Are aluminum square tubes recyclable?

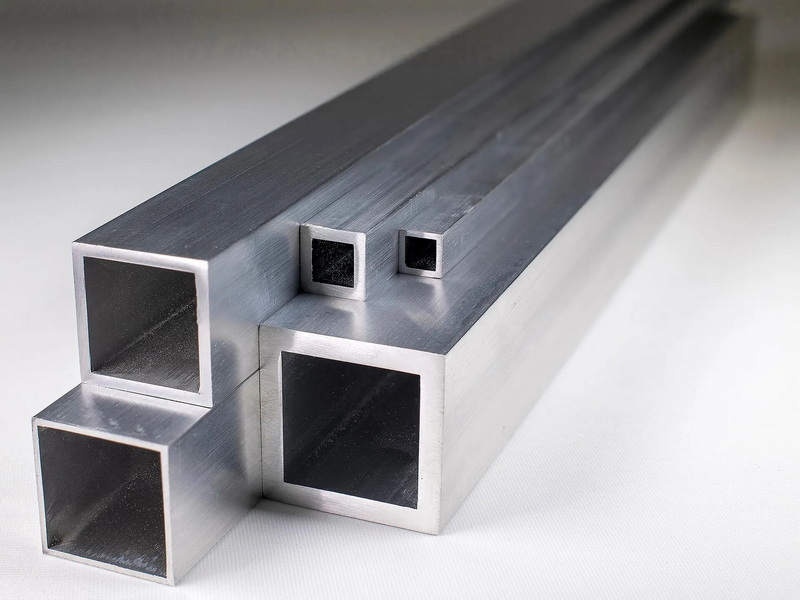

Aluminum square tubes are essential components in various industries, including construction, automotive, furniture, and architectural design. Their lightweight, corrosion resistance, and versatility make them a preferred choice for structural and decorative applications. The UK hosts several leading manufacturers and suppliers of aluminum square tubes, offering a wide range of sizes, grades, and finishes to meet diverse engineering and design needs. This article explores the top aluminum square tube manufacturers and suppliers in the UK, highlighting their product offerings, services, and industry expertise.

Aluminum square tubes are hollow, square-shaped extrusions made from aluminum alloys, commonly the 6000 series, which is known for its excellent corrosion resistance and versatility. These tubes are used in frameworks, supports, railings, furniture, and more due to their strength-to-weight ratio and ease of fabrication.

- Lightweight yet strong

- Corrosion-resistant

- Available in various thicknesses and sizes

- Suitable for welding, machining, and finishing

- Commonly supplied in 5-meter standard lengths with custom cutting options

Aluminum square tubes offer several advantages over other materials such as steel or wood. Their lightweight nature reduces transportation and handling costs, while their corrosion resistance eliminates the need for frequent maintenance or protective coatings. Additionally, aluminum's excellent thermal and electrical conductivity makes these tubes suitable for specialized applications in electronics and heat exchangers. The aesthetic appeal of aluminum, especially when anodized or powder-coated, also makes it a favored choice for visible architectural elements.

Smiths Metal Centres is a world-class supplier of engineering raw materials, including a vast range of aluminum tubing products such as round, rectangular, and square tubes. They stock multiple grades and specifications, processing tubes in-house at their central warehouse in Biggleswade and through a network of 13 UK service centers. This ensures local expertise and fast supply chain solutions for customers ranging from small machine shops to large multinational corporations.

Product Highlights:

- Extensive stock of aluminum square tubes

- In-house processing and cutting services

- Local service centers for quick delivery and support

- Ability to supply custom lengths and profiles

Smiths Metal Centres also provides technical support and material certification, ensuring that customers receive products that meet stringent industry standards. Their commitment to quality and service has made them a trusted partner for OEMs and fabricators across the UK.

Aluminium Online is one of the UK's leading suppliers of high-quality aluminum extrusions, including a broad selection of 6000-series aluminum square tubes certified to BSEN755 standards. They offer next-day delivery on thousands of products ordered before 1 pm, making them a reliable choice for urgent projects.

Product Range:

- Square tubes from 12.7mm x 12.7mm to 38.1mm x 38.1mm

- Various thicknesses including 1.5mm, 1.6mm, 3mm, and 3.3mm

- Finishes: mill finish, anodized, and powder-coated options in multiple RAL colors

- Custom length cutting available

Aluminium Online also provides detailed product datasheets and machining guides, helping customers select the right material for their applications. Their user-friendly website and customer service team make ordering and logistics seamless.

Metals4U supplies aluminum box sections and square tubes with a focus on quality and service. They cater to various industries needing precision aluminum extrusions and offer expert advice on material selection and applications.

Their stock includes a wide range of sizes and alloys, and they provide cutting to length, drilling, and fabrication services. Metals4U is known for quick turnaround times and competitive pricing, making them a popular choice for both small-scale fabricators and large industrial clients.

Metals Warehouse offers high-quality aluminum square tubes sourced from reputable mills with a standard length of 5 meters. They specialize in the 6000 series aluminum for its corrosion resistance and versatility, providing bespoke cutting services to meet specific customer requirements.

Advantages:

- High thermal and electrical conductivity of aluminum

- Malleable and ductile properties ideal for architecture and design

- Custom thickness and length options

- Competitive pricing with volume discounts

Metals Warehouse also provides comprehensive technical support and can assist with material certification and compliance documentation, ensuring peace of mind for quality-conscious buyers.

Metalex is a leading UK-based aluminum tube supplier with an extensive stock of aluminum tubes, including square tubes. They provide professional service and cater to a broad customer base across multiple sectors.

Metalex focuses on delivering consistent quality and fast delivery, with the ability to handle large orders for OEMs and wholesalers. Their expertise in aluminum extrusion and finishing processes enables them to offer tailored solutions for demanding applications.

Aluminum square tubes are highly versatile and find applications in a wide range of industries:

- Construction: Used extensively in frameworks, supports, and structural elements in buildings. Their corrosion resistance makes them ideal for outdoor and marine environments.

- Architectural: Employed in railings, curtain walls, window frames, and decorative facades due to their aesthetic appeal and durability.

- Furniture: Lightweight frames for chairs, tables, shelving, and storage units benefit from aluminum's strength and finish options.

- Automotive: Used in structural components, protective frames, and custom fabrication for vehicles and trailers.

- Industrial: Machine guards, conveyor supports, and custom fabrication projects rely on aluminum square tubes for their strength and ease of machining.

- DIY and Home Improvement: Popular among hobbyists and professionals for garden structures, shelving, and custom metalwork.

Understanding the manufacturing process helps appreciate the quality and versatility of aluminum square tubes:

1. Extrusion: Aluminum billets are heated and forced through a shaped die to create a continuous hollow square tube profile.

2. Cooling: The extruded tubes are cooled, typically by air or water quenching, to achieve the desired mechanical properties.

3. Stretching: Tubes are stretched to straighten and relieve internal stresses.

4. Cutting: Standard lengths (usually 5 meters) are cut, with custom lengths available per customer requirements.

5. Finishing: Tubes may be anodized, powder-coated, or mechanically polished to enhance corrosion resistance and aesthetics.

6. Quality Control: Dimensional checks, surface inspections, and mechanical testing ensure compliance with standards like BSEN755.

Choosing UK-based aluminum square tube manufacturers and suppliers offers several benefits:

- Proximity: Reduced lead times and shipping costs compared to overseas suppliers.

- Quality Assurance: Compliance with British and European standards ensures high product quality.

- Customization: Easier communication for bespoke orders, including custom alloys, sizes, and finishes.

- Technical Support: Access to expert advice and after-sales service.

- Sustainability: Many UK suppliers emphasize environmentally friendly practices and recycling of aluminum.

The UK market offers a robust selection of aluminum square tube manufacturers and suppliers that cater to diverse industrial and commercial needs. Companies like Smiths Metal Centres, Aluminium Online, Metals4U, Metals Warehouse, and Metalex provide high-quality products with various grades, sizes, finishes, and custom services. These suppliers ensure timely delivery and expert support, making them ideal partners for projects requiring durable and versatile aluminum square tubes. Whether for architectural applications, furniture design, or industrial frameworks, UK suppliers deliver reliable materials that meet stringent quality standards.

By choosing UK-based aluminum square tube manufacturers and suppliers, buyers benefit from quality assurance, customization options, and sustainable sourcing, ensuring their projects are supported by premium materials and professional service.

A1: The 6000 series aluminum alloys are most common due to their excellent corrosion resistance and versatility. Grades like 6060 and 6063 are popular choices.

A2: Yes, many suppliers offer powder-coated finishes in various RAL colors for enhanced aesthetics and protection against corrosion.

A3: Sizes typically range from small dimensions like 12.7mm x 12.7mm up to larger sizes such as 38.1mm x 38.1mm, with thicknesses from 1.5mm to over 3mm.

A4: Yes, most leading suppliers provide bespoke cutting services to meet specific length requirements, often with quick turnaround times.

A5: Construction, architecture, automotive, furniture manufacturing, industrial machinery, and DIY sectors are primary users of aluminum square tubes.

A6: Aluminum is lighter but generally less strong than steel. However, its corrosion resistance and ease of fabrication often make it a better choice for many applications.

A7: Yes, aluminum is 100% recyclable without loss of properties, making aluminum square tubes an environmentally friendly choice.

Seven Requirements for External Doors And Windows of Passive Rooms

How Much Do You Know about The Design Standards for Aluminum Alloy Door And Window Dimensions?

Welding Vs Stainless Steel Fabrication: Understanding The Manufacturing Process Differences

Stainless Steel Fabrication Vs Powder Coated Steel: Durability And Cost Comparison

CNC Machining Vs Stainless Steel Fabrication: Pros And Cons for Industrial Use

Stainless Steel Fabrication Vs Carbon Steel Fabrication: Key Differences Explained

Stainless Steel Fabrication Vs Aluminum Fabrication: Which Is Right for Your Project?

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?