English

Views: 222 Author: Tomorrow Publish Time: 2025-06-29 Origin: Site

Content Menu

● Understanding Aluminum Square Tubes

>> Key Benefits of Aluminum Square Tubes

>> Common Aluminum Alloys Used in Square Tubes

● Leading Aluminum Square Tube Manufacturers and Suppliers in the USA

● Applications of Aluminum Square Tubes

>> Architectural and Decorative Uses

>> Industrial and Structural Applications

● Choosing the Right Aluminum Square Tube Manufacturer

● Quality Assurance and Industry Standards

● Sustainability and Environmental Considerations

● Innovations in Aluminum Square Tube Manufacturing

● Frequently Asked Questions (FAQs)

>> Q1: What is the difference between 6061 and 6063 aluminum alloys in square tubes?

>> Q2: Can aluminum square tubes be welded?

>> Q3: Are aluminum square tubes suitable for outdoor use?

>> Q4: What sizes of aluminum square tubes are commonly available?

>> Q5: Do manufacturers offer custom aluminum square tube fabrication?

>> Q6: How do I ensure the quality of aluminum square tubes I purchase?

>> Q7: Can aluminum square tubes be anodized or powder-coated?

Aluminum square tubes are essential components in various industries, including construction, fabrication, automotive, and architectural design. Their lightweight nature, combined with strength and corrosion resistance, makes them highly versatile for structural and decorative applications. This article explores the top aluminum square tube manufacturers and suppliers in the USA, highlighting their product offerings, manufacturing capabilities, and value-added services. We also provide visual content to illustrate the quality and applications of aluminum square tubes and conclude with frequently asked questions to assist buyers and industry professionals.

Aluminum square tubes are hollow extrusions with a square cross-section, commonly used for structural frameworks, supports, and decorative elements. They are typically made from aluminum alloys such as 6061 and 6063, which offer excellent strength, corrosion resistance, and workability. Square tubes can have sharp or rounded corners and vary in wall thickness and size to meet different engineering requirements.

- Lightweight yet strong: Ideal for applications requiring strength without excessive weight.

- Corrosion resistance: Suitable for outdoor and marine environments.

- Versatile sizes: Available in a range of dimensions to fit specific project needs.

- Ease of fabrication: Can be welded, cut, machined, and formed easily.

- Aesthetic appeal: Smooth finishes and clean lines for architectural use.

Among the many aluminum alloys, 6061 and 6063 are the most prevalent for square tubing. The 6061 alloy is known for its superior mechanical properties, making it ideal for structural applications requiring high strength and durability. On the other hand, 6063 alloy is prized for its excellent surface finish and corrosion resistance, often used in architectural and decorative projects. Understanding the alloy differences helps in selecting the right aluminum square tube for your specific needs.

Eagle Aluminum offers a comprehensive range of aluminum square tubing designed for superior strength and durability. Their products come with precise dimensions and smooth finishes, suitable for construction, fabrication, and custom projects. Eagle Aluminum provides various sizes, including 1/2" x .080 wall and 1-1/2" x 1/4" wall tubing, with options for sharp or radius corners. They emphasize reliability and versatility in their aluminum solutions.

Pierce Aluminum supplies aluminum square tubes along with full processing and fabrication services across 10 U.S. locations. Their square tube products feature either square or radius corners and are ideal for structural applications requiring lightweight materials. Pierce Aluminum offers both straight lengths and coiled forms, catering to diverse project specifications.

Hydro Extrusion is North America's premier supplier of aluminum tubing, including square, rectangular, and round profiles. Their aluminum square tubes are available in sizes from 1/2 inch to 8 inches per side, with wall thicknesses ranging from 1/8 inch to 1/2 inch. Hydro produces tubes from 6061 and 6063 alloys, offering excellent finishing qualities and corrosion resistance. Their expertise extends to custom extrusions up to 20 inches in diameter, supported by advanced tooling and engineering services.

Eastern Metal Supply stocks aluminum square tube extrusions in various alloys, including 6063-T52, 6061-T6, and 6005A-T61. They offer a wide selection of sizes and wall thicknesses, with options for radius or sharp corners. Their inventory includes lengths up to 24 feet, supporting both small-scale and large projects.

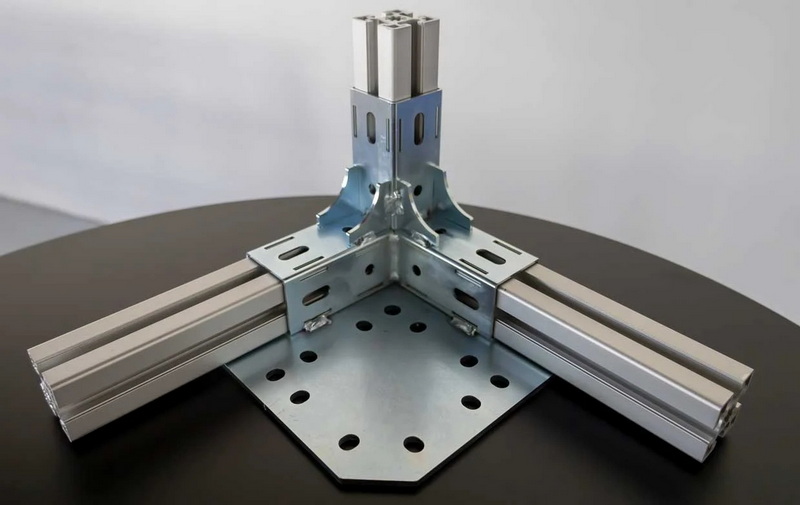

Orange Aluminum specializes in square aluminum tubing connectors and supplies a variety of square tube products suitable for structural and decorative uses. Their focus on connectors complements the aluminum square tubes, offering integrated solutions for fabrication and assembly.

Aluminum square tubes are widely used in:

- Construction: Frameworks, supports, scaffolding, and curtain walls.

- Architectural Design: Railings, window frames, and decorative facades.

- Automotive and Marine: Lightweight chassis components and structural supports.

- Furniture Manufacturing: Frames for all-aluminum furniture and fixtures.

- Home Improvement: Aluminum doors, windows, and protective barriers.

In modern architecture, aluminum square tubes are favored for their clean lines and ability to be anodized or powder-coated in various colors. This makes them perfect for visible structural elements like balustrades, handrails, and decorative screens. Their corrosion resistance ensures longevity even in harsh weather conditions, making them suitable for both indoor and outdoor installations.

Industries rely on aluminum square tubes for their strength-to-weight ratio. They are used in conveyor systems, machine frames, and support structures where reducing weight without sacrificing strength is critical. Aluminum's non-magnetic and non-sparking properties also make these tubes ideal for specialized environments such as electrical enclosures and chemical plants.

When selecting a manufacturer or supplier, consider the following factors:

- Alloy options: Ensure availability of alloys like 6061 or 6063 for your application.

- Size and thickness range: Confirm the supplier can provide the dimensions you require.

- Fabrication capabilities: Look for suppliers offering cutting, bending, welding, and finishing services.

- Delivery and logistics: Reliable shipping and inventory management are critical.

- Customer support: Technical assistance and customization options enhance project success.

- Certifications and quality standards: ISO certifications and compliance with ASTM standards guarantee product quality.

Top manufacturers adhere to strict quality control processes and industry standards such as ASTM B221 for aluminum extrusions. These standards ensure consistent mechanical properties, dimensional accuracy, and surface finish. Many suppliers provide mill test reports (MTRs) and certifications to validate the quality of their aluminum square tubes, which is vital for critical applications.

Aluminum is highly recyclable, and many manufacturers incorporate recycled content into their products. Choosing suppliers committed to sustainable practices not only reduces environmental impact but also aligns with green building certifications such as LEED. Additionally, aluminum's long lifecycle and corrosion resistance contribute to reduced maintenance and replacement costs.

Recent advancements include:

- Enhanced extrusion techniques: Improved tooling and processes allow for tighter tolerances and complex profiles.

- Surface treatments: Anodizing, powder coating, and fluoropolymer finishes increase durability and aesthetic options.

- Smart tubing: Integration of sensors and coatings that monitor structural health in real-time.

- Lightweight composites: Combining aluminum tubes with composite materials for enhanced performance in aerospace and automotive sectors.

These innovations expand the possibilities for aluminum square tubes across emerging industries and applications.

The USA hosts a robust network of aluminum square tube manufacturers and suppliers capable of meeting diverse industrial and architectural needs. Companies like Eagle Aluminum, Pierce Aluminum, Hydro Extrusion, Eastern Metal Supply, and Orange Aluminum provide high-quality products with various alloy options, sizes, and fabrication services. Selecting the right supplier depends on project specifications, alloy preferences, and support services. Aluminum square tubes remain a versatile and reliable choice for engineers, fabricators, and designers seeking durable, lightweight structural materials. With ongoing innovations and a focus on sustainability, the future of aluminum square tube manufacturing in the USA looks promising.

A1: 6061 alloy offers higher strength and is suitable for structural applications, while 6063 is preferred for architectural uses due to its superior finishing qualities.

A2: Yes, aluminum square tubes are easily welded using standard techniques, especially those made from 6061 and 6063 alloys.

A3: Yes, aluminum's corrosion resistance makes square tubes ideal for outdoor environments, including marine applications.

A4: Sizes typically range from 1/2 inch to 8 inches per side, with wall thicknesses from 1/16 inch to 1/2 inch depending on the manufacturer.

A5: Many manufacturers provide custom cutting, bending, and finishing services to meet specific project requirements.

A6: Request mill test reports (MTRs), verify compliance with ASTM standards, and choose suppliers with ISO certifications.

A7: Yes, both anodizing and powder coating are common surface treatments that enhance corrosion resistance and aesthetics.

Seven Requirements for External Doors And Windows of Passive Rooms

How Much Do You Know about The Design Standards for Aluminum Alloy Door And Window Dimensions?

Welding Vs Stainless Steel Fabrication: Understanding The Manufacturing Process Differences

Stainless Steel Fabrication Vs Powder Coated Steel: Durability And Cost Comparison

CNC Machining Vs Stainless Steel Fabrication: Pros And Cons for Industrial Use

Stainless Steel Fabrication Vs Carbon Steel Fabrication: Key Differences Explained

Stainless Steel Fabrication Vs Aluminum Fabrication: Which Is Right for Your Project?

Stainless Steel Grades 201 Vs 304: Cost Vs Performance Breakdown

316L Vs 316 Stainless Steel Grades: Which Is Better for Corrosion Resistance?

Comparing Austenitic Vs Martensitic Stainless Steel Grades: What You Need To Know?